Tungsten Carbide C hom pob qhov ntswg Rotary Burrs

Qhov zoo

KHOOM PLIG

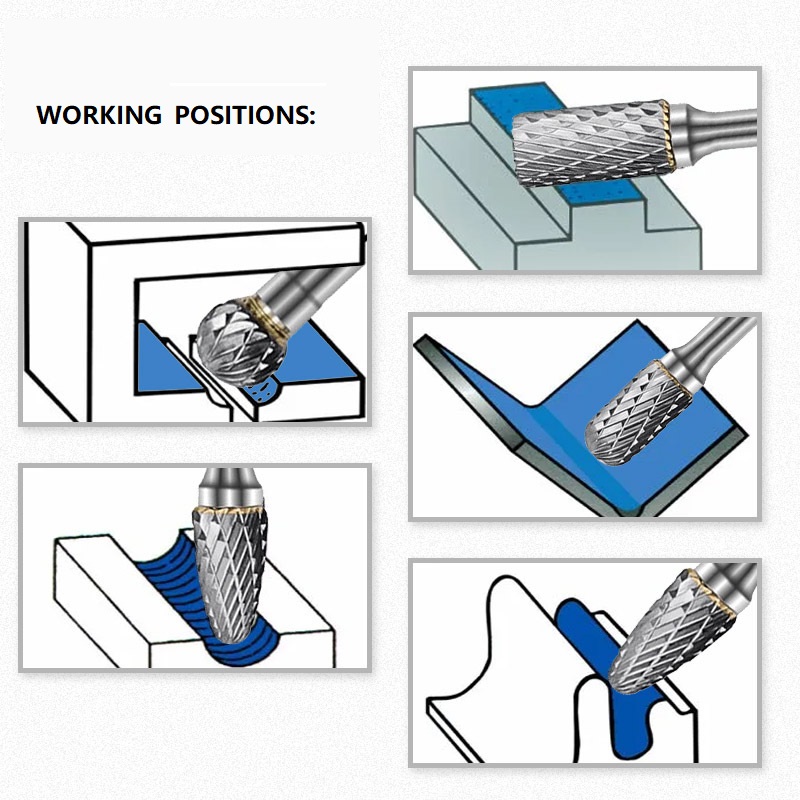

1. Txo cov chipping thiab tawg: lub pob qhov ntswg tsim kom txo tau qhov kev pheej hmoo ntawm chipping los yog tawg cov khoom uas tau ua hauj lwm, tshwj xeeb tshaj yog nyob rau hauv ilv qhov chaw los yog thaum ua hauj lwm nrog nkig. Qhov no pab tiv thaiv kev puas tsuaj thiab ua kom muaj qib siab dua.

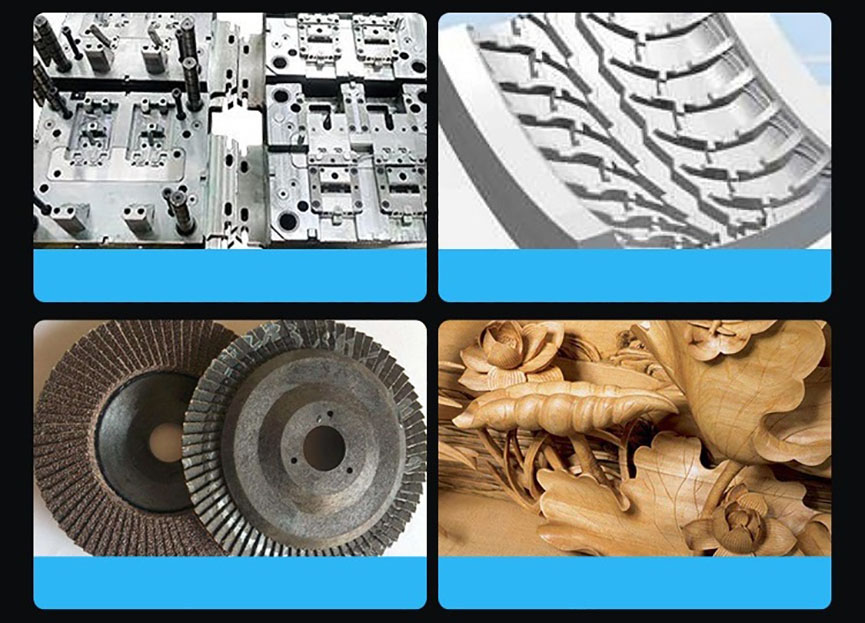

2. Versatility thiab Flexibility: C hom pob qhov ntswg burrs tuaj yeem siv rau ntau yam ntaub ntawv, suav nrog hlau, yas, ntoo, thiab cov khoom sib xyaw. Lawv yog cov zoo tagnrho rau cov dej num xws li kev sib tov, shaping, thiab smoothing, ua rau lawv muaj ntau yam rau ntau yam kev siv thiab kev lag luam.

3. Kev tshem tawm cov khoom lag luam zoo: Thaum siv feem ntau rau kev ua tiav, C hom pob qhov ntswg burrs tuaj yeem tshem tawm cov khoom lag luam zoo thaum xav tau. Lawv cov ntawv sib npaug tso cai rau kev tswj xyuas cov khoom tshem tawm thiab contouring nyob rau hauv qhov chaw nruj lossis qhov chaw nyuaj.

4. Kev Ua Haujlwm Ntev Ntev: Tungsten carbide C hom pob qhov ntswg burrs yog qhov ruaj khov thiab tuaj yeem tiv taus kev ua haujlwm siab ceev. Lawv tuav lawv cov ntse thiab txiav ua tau zoo nyob rau lub sijhawm ntev, txo qhov xav tau kev hloov pauv thiab txhim kho cov khoom tsim tau.

5. Thaum tshav kub kub Resistance: Tungsten carbide paub txog nws cov cua kub tsis kam. C hom pob qhov ntswg burrs tuaj yeem tiv taus cov cua sov tsim thaum lub sij hawm txiav, tiv thaiv overheating thiab tswj lawv cov kev ua tau zoo thiab kev ua haujlwm ntev.

6. Kev sib xyaw ua ke: C hom pob qhov ntswg burrs yog tsim los siv nrog cov cuab yeej siv hluav taws xob ceev xws li cov tshuab tua hluav taws xob lossis cov khoom siv hluav taws xob. Lawv tau sib xws nrog ntau yam cuab yeej tsim khoom siv, ua rau lawv yooj yim siv thiab siv dav.