T hom khoom Carbide End Mill

Nta

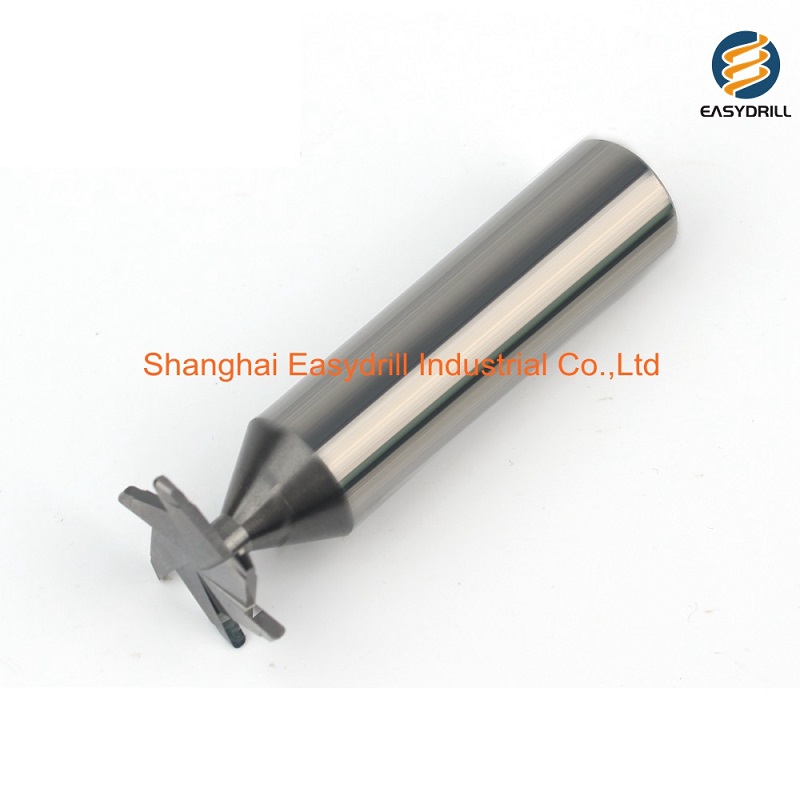

T-shaped khoom carbide kawg mills paub txog lawv cov kev ua tau zoo thiab kev txiav txim siab muaj peev xwm. Qee qhov tseem ceeb ntawm T-shaped khoom carbide kawg mills suav nrog:

1. Khoom carbide qauv: T-zoo li tus kawg mills yog ua los ntawm cov khoom carbide, uas muaj zoo heev hardness, hnav tsis kam thiab kub tsis kam, yog li ncua lub neej ntawm cov cuab yeej thiab txhim kho kev ua tau zoo.

2. Variable Geometry: T-shaped kawg mills feem ntau muaj qhov sib txawv geometry uas pab nrog kev khiav tawm ntawm nti, txo cov quab yuam txiav, thiab txhim kho qhov chaw tiav.

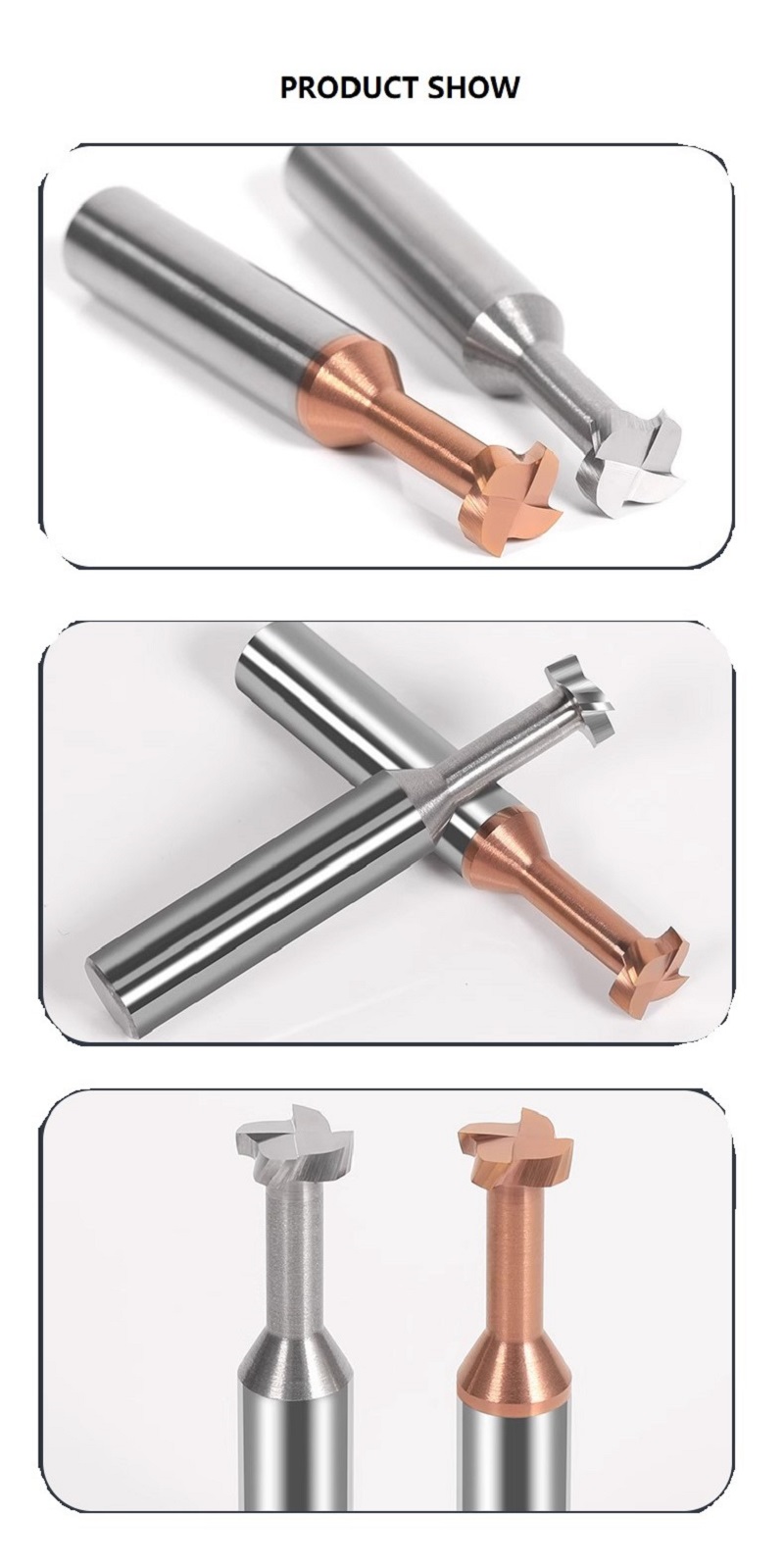

3. Lub kaum sab xis siab: Lub kaum sab xis siab ntawm T-hom kawg mills tuaj yeem ua tiav cov nti tshem tawm thiab txhim kho kev ua haujlwm ntawm kev txiav, tshwj xeeb tshaj yog nyob rau hauv high-speed machining daim ntaub ntawv.

4. Center txiav tsim: Ntau T-hom kawg mills yog tsim los nrog nruab nrab txiav muaj nuj nqi, tso cai rau plunge txiav thiab ramping ua hauj lwm.

5. Ntau yam txheej txheej: T-hom kawg mills muaj ntau txoj kev xaiv txheej, xws li TiAlN, TiCN thiab AlTiN, uas tuaj yeem txhim kho hnav tsis kam, txo kev sib txhuam thiab txhim kho lub neej ntawm cov cuab yeej.

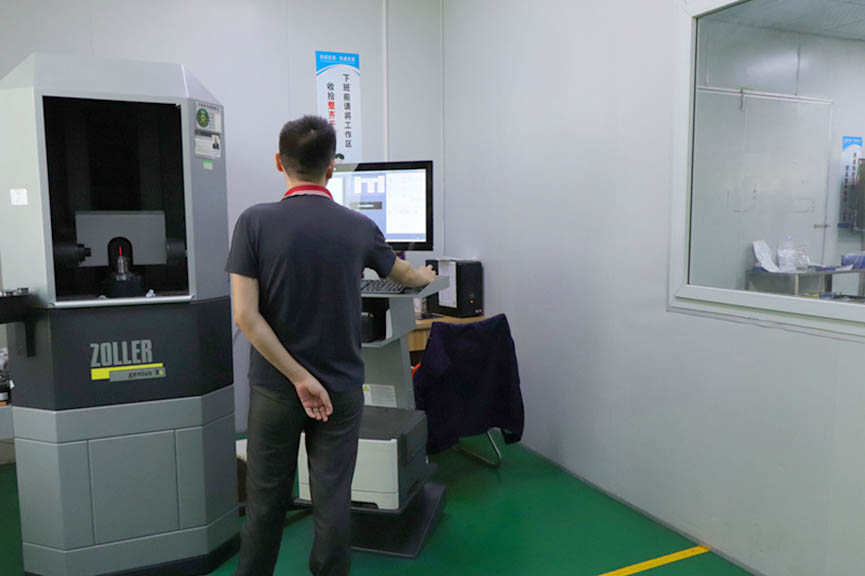

6. Precision hauv av txiav ntug: T-hom kawg mills yog tsim nrog precision hauv av txiav npoo kom paub meej thiab ua haujlwm zoo ib yam.

7. Ntau qhov ntau thiab tsawg thiab kev teeb tsa: T-shaped kawg mills muaj nyob rau hauv ntau qhov ntau thiab tsawg, zawj lengths, thiab configurations kom tau raws li qhov sib txawv machining yuav tsum tau thiab kev siv.

KHOOM PLIG

KHOOM PLIG