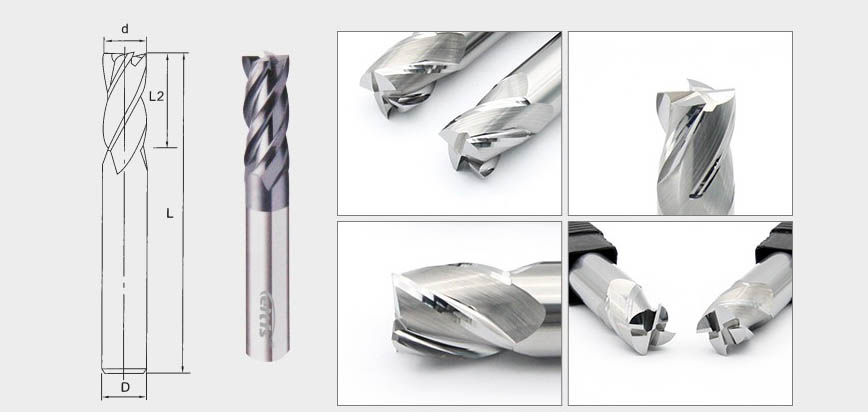

Khoom Carbide Square End Mills rau kev machining

Nta

1. Khoom siv: Cov khoom carbide square kawg mills yog tsim los ntawm ib qho ntawm cov khoom siv carbide, uas ua kom muaj kev ruaj khov thiab tiv taus hnav thiab tsim kua muag.

2. Hardness: Carbide paub txog nws qhov tshwj xeeb hardness. Khoom carbide square kawg mills tuaj yeem tiv taus siab txiav ceev thiab tswj lawv qhov ntse kom ntev dua piv rau lwm cov ntaub ntawv.

3. Precision: Khoom carbide square kawg mills yog tsim los nrog precision hauv siab. Lawv muaj peev xwm ua tau zoo thiab huv si txiav, ua rau cov neeg ua haujlwm zoo thiab ua haujlwm zoo.

4. Versatility: Cov mills kawg no tuaj yeem siv ntau yam ntaub ntawv, suav nrog cov hlau tsis muaj hlau, yas, thiab cov khoom sib xyaw. Qhov no versatility ua rau lawv haum rau ntau yam kev siv machining.

5. Kev ua tau zoo: Cov khoom carbide square kawg mills yog tsim los nrog ntau lub flutes, uas txhim kho nti khiav tawm thiab txo qhov muaj feem cuam tshuam. Qhov no txhim kho machining efficiency thiab tag nrho productivity.

6. Thaum tshav kub kub tsis kam: Carbide muaj cov khoom siv hluav taws xob zoo heev, tso cai rau cov khoom carbide square kawg mills tuaj yeem tiv taus qhov kub thiab txias tsim thaum lub sijhawm txiav kev ua haujlwm yam tsis poob lawv qhov hardness lossis sharpness.

7. Lub neej ntev: Vim lawv cov hardness siab thiab durability, cov khoom carbide square kawg mills muaj lub neej ntev dua piv rau lwm hom kawg mills. Qhov no ua rau tsawg dua cov cuab yeej hloov, txo cov sijhawm poob thiab cov nqi.

8. High rigidity: Cov khoom carbide kawg mills muaj siab rigidity, txhais tau tias lawv tsis tshua yuav khoov lossis deflect thaum lub sijhawm ua haujlwm. Qhov rigidity no ua rau kev txhim kho kev ruaj ntseg thiab qhov tseeb ntawm qhov ntev.

9. Cov txheej txheem txheej: Cov khoom carbide square kawg mills kuj tuaj yeem coated nrog ntau txheej txheej xws li TiN, TiCN, thiab TiAlN, uas ntxiv dag zog rau lawv cov kev ua tau zoo los ntawm kev txo cov kev sib txhuam, ua kom lub neej ntev, thiab txhim kho nti khiav tawm.

10. Cutting-edge geometry: Cov khoom carbide square kawg mills muaj nyob rau hauv ntau yam txiav-ntug geometry, xws li ncaj, helical, thiab sib txawv helix tsim. Cov geometry no muab cov yam ntxwv sib txawv thiab ua raws li cov kev xav tau ntawm machining.

nthuav dav

Factory

Qhov zoo

1. Durability: Khoom carbide square kawg mills paub txog lawv qhov tshwj xeeb durability. Cov khoom siv carbide tiv taus hnav thiab tuaj yeem tiv taus kev txiav nrawm thiab cov ntaub ntawv abrasive, ua rau lub neej ntev dua.

2. High Speed Machining: Cov khoom carbide square kawg mills tuaj yeem ua haujlwm siab ceev machining vim lawv hardness thiab kub tsis kam. Qhov no tso cai rau cov khoom tsim tau ntau ntxiv thiab lub sijhawm ua haujlwm luv.

3. Chip Evacuation zoo heev: Cov flutes ntawm cov khoom carbide square kawg mills yog tsim los ua kom zoo dua nti khiav tawm. Qhov no pab tiv thaiv chip build-up thiab xyuas kom meej txiav, txo cov kev pheej hmoo ntawm cov cuab yeej puas los yog workpiece tsis xws luag.

4. Txhim kho Nto tiav: Cov khoom carbide square kawg mills tsim cov kev txiav kom huv thiab meej, ua rau muaj qhov zoo tshaj plaws ntawm qhov chaw ua haujlwm. Qhov no tshem tawm qhov xav tau ntawm cov txheej txheem ua tiav, txuag lub sijhawm thiab tus nqi.

5. Versatility: Khoom carbide square kawg mills yog tsim rau ntau yam ntaub ntawv, xws li hlau, yas, thiab composites. Qhov versatility no ua rau lawv zoo tagnrho rau ntau yam kev lag luam, los ntawm tsheb mus rau aerospace.

6. Txhim khu kev ruaj ntseg: Khoom carbide square kawg mills feature siab rigidity, uas txo cov cuab yeej deflection thiab txhim khu kev ruaj ntseg. Qhov no ua rau kev txhim kho qhov tseeb qhov tseeb thiab txo qhov muaj feem ntawm cov cuab yeej tawg.

7. Precision Machining: Lub ntse txiav npoo ntawm cov khoom carbide square kawg mills tso cai rau kev ua haujlwm zoo thiab raug. Qhov no yog qhov tseem ceeb heev rau cov ntawv thov uas yuav tsum tau ua kom nruj nruj thiab nthuav dav.

8. Thaum tshav kub kub Resistance: Khoom carbide kawg mills tuaj yeem tiv taus qhov kub thiab txias tsim thaum lub sijhawm ua haujlwm. Qhov kev tiv thaiv tshav kub no tiv thaiv lub cuab yeej los ntawm softening lossis poob nws cov khoom txiav, ua kom muaj kev ua tau zoo ib yam.

9. Txo cov cuab yeej hloov pauv: Cov khoom siv carbide square kawg mills muaj lub neej ntev ntawm cov cuab yeej piv rau lwm cov ntaub ntawv, txo cov kev xav tau ntawm cov cuab yeej hloov tas li. Qhov no ua rau kom muaj zog ntau lawm efficiency thiab txo downtime.

10. Nqi-Effectiveness: Txawm hais tias pib kim dua, cov khoom carbide square kawg mills muab kev txuag nyiaj mus sij hawm ntev vim lawv cov cuab yeej txuas ntxiv thiab muaj peev xwm ua tau zoo. Qhov no ua rau lawv xaiv tus nqi zoo rau kev tsim khoom.

| Txoj kab uas hla (mm) | Hniav ntev (mm) | Puv (mm) | Qhov siab (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 ib | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 ib | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 ib | 23 | 75 | 10 |

| 9.5 ib | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 Nws | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 Nws | 30 | 75 | 12 |

| 13.0 Nws | 45 | 100 | 14 |

| 14.0 Nws | 45 | 100 | 14 |

| 15.0 Nws | 45 | 100 | 16 |

| 16.0 Nws | 45 | 100 | 16 |

| 17.0 Nws | 45 | 100 | 18 |

| 18.0 Nws | 45 | 100 | 18 |

| 19.0 Nws | 45 | 100 | 20 |

| 20.0 Nws | 45 | 100 | 20 |

| 22.0 Nws | 45 | 100 | 25 |

| 25.0 Nws | 45 | 100 | 25 |