Khoom Carbide Tshuab Reamer nrog Kauv Flute

Qhov zoo

1. Superior Hardness thiab Wear Resistance: Cov khoom carbide yog cov khoom siv tawv heev thiab ruaj khov uas tuaj yeem tiv taus siab txiav ceev thiab tuav nws cov txiav rau lub sijhawm ntev. Qhov hardness thiab hnav tsis kam ua rau cov khoom siv carbide reamers zoo tagnrho rau siv hauv kev thov thiab cov khoom siv.

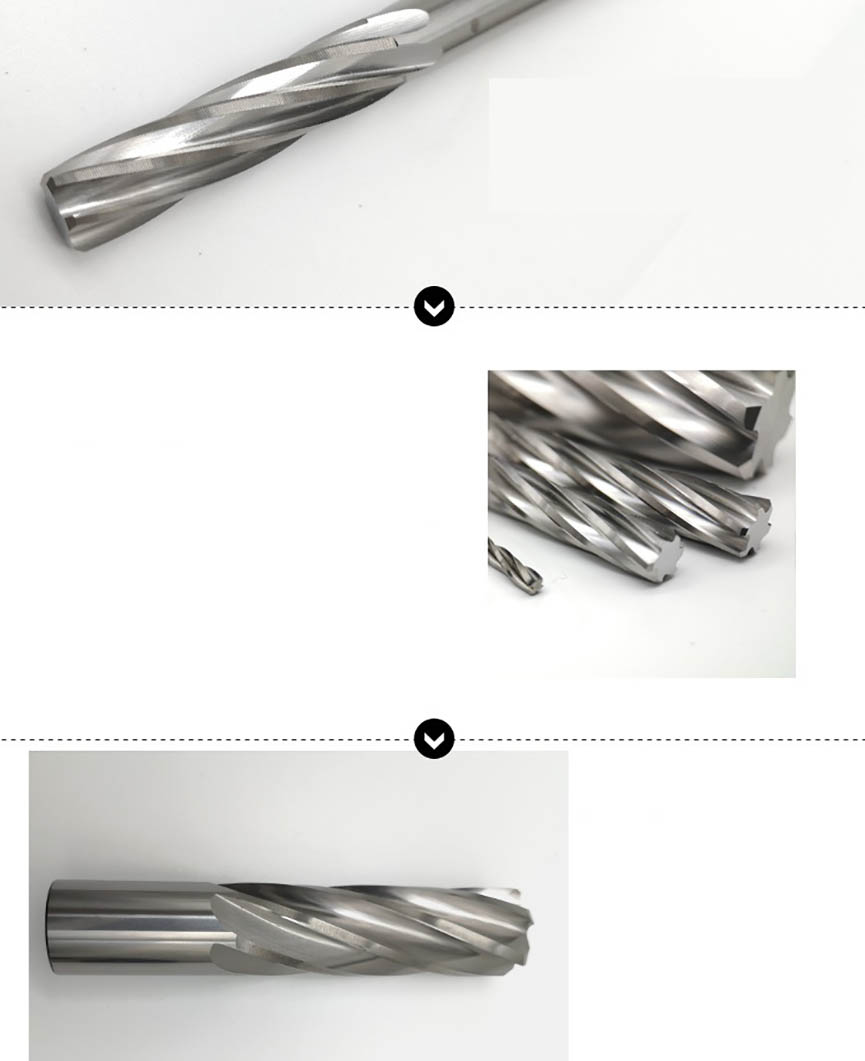

2. Chip Evacuation zoo heev: Lub kauv flute tsim ntawm cov khoom carbide tshuab reamers tso cai rau kev khiav tawm ntawm nti thaum lub sij hawm reaming. Cov kauv flutes pab tiv thaiv nti clogging los yog jamming, txhim khu lub reamer txoj kev ua tau zoo thiab tsim tau.

3. Ua kom nrawm nrawm: Vim lawv cov hardness zoo dua, cov khoom siv carbide reamers tuaj yeem siv rau ntawm kev txiav nrawm dua li lwm cov ntaub ntawv reamer. Qhov no tso cai rau kom nrawm dua thiab ua haujlwm tau zoo dua, txo lub sijhawm ua haujlwm thiab txhawb nqa cov khoom lag luam.

4. Enhanced Surface Finish: Khoom carbide tshuab reamers nrog kauv flutes tsim ib tug smoother nto tiav ntawm lub machined qhov. Kev teeb tsa ntawm lub raj raj txuas pab txo qis kev sib tham thiab kev co thaum lub sij hawm txiav, ua rau lub qhov zoo thiab qhov tseeb.

5. Lub neej ntev dua: Cov khoom siv carbide reamers muaj lub neej ntev dua piv rau lwm cov ntaub ntawv reamer. Lawv lub siab hnav tsis kam thiab toughness tso cai rau lawv tiv taus cov kev xav tau uas tau ntsib thaum lub sijhawm reaming, txo qhov zaus ntawm cov cuab yeej hloov pauv thiab cuam tshuam rau lub sijhawm poob.

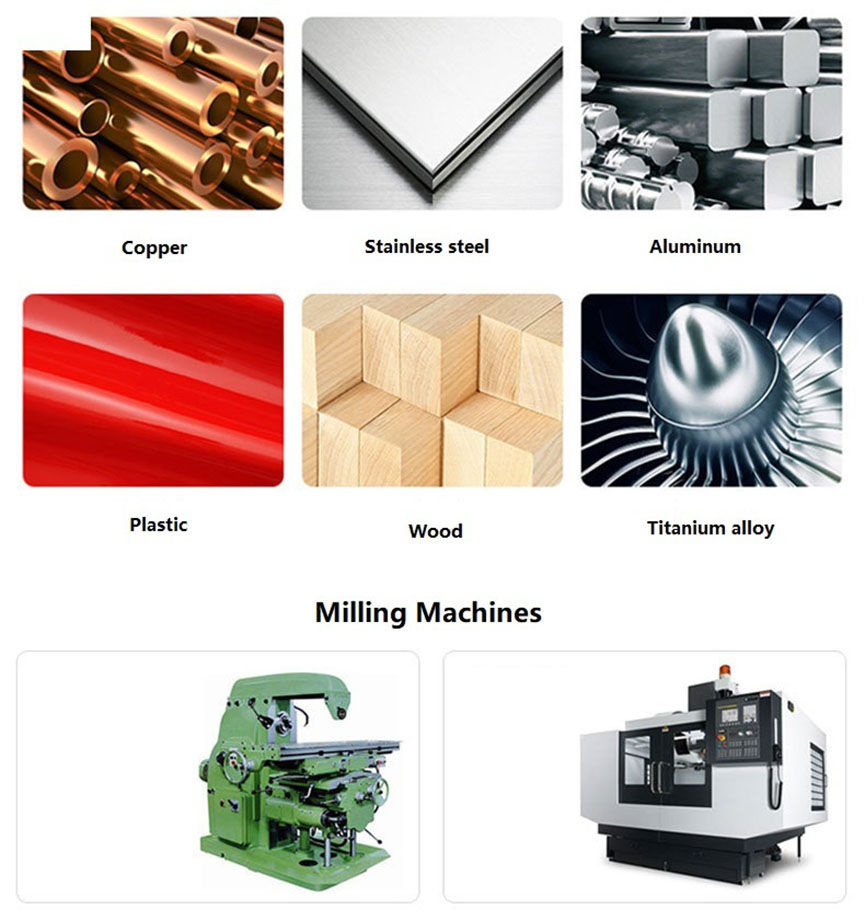

6. Versatility: Khoom carbide tshuab reamers nrog kauv flute yuav siv tau nyob rau hauv ntau yam ntaub ntawv, xws li steels, stainless hlau, cam khwb cia hlau, thiab non-ferrous hlau. Lawv tuaj yeem tuav ob qho tib si cuam tshuam thiab kev ua haujlwm txuas ntxiv ntawm ntau yam khoom siv ua haujlwm.

7. Ntau Reamer Stability: Cov kauv raj nplaim tsim ntawm cov reamers no pab txhim kho kev ruaj ntseg thaum lub sij hawm txiav. Qhov no minimizes deflection, tiv thaiv kev sib tham, thiab xyuas kom meej ntau thiab concentric qhov tsim.

8. Dimensional Accuracy: Khoom carbide tshuab reamers yog tsim los rau nruj tolerances, muab zoo heev dimensional raug thiab sib xws. Qhov no ua rau lawv haum rau cov ntawv thov uas xav tau lub qhov taub qhov taub meej thiab nruj tolerances.

9. Txo cov cuab yeej tu: Vim lawv qhov tshwj xeeb hardness thiab hnav tsis kam, khoom carbide tshuab reamers yuav tsum tsis tshua muaj sharpening thiab txij nkawm piv rau lwm hom reamer. Qhov no txo cov sij hawm thiab kev siv zog siv rau kev tu cov cuab yeej thiab tso cai rau kev ua haujlwm tsis muaj kev cuam tshuam ntau dua.

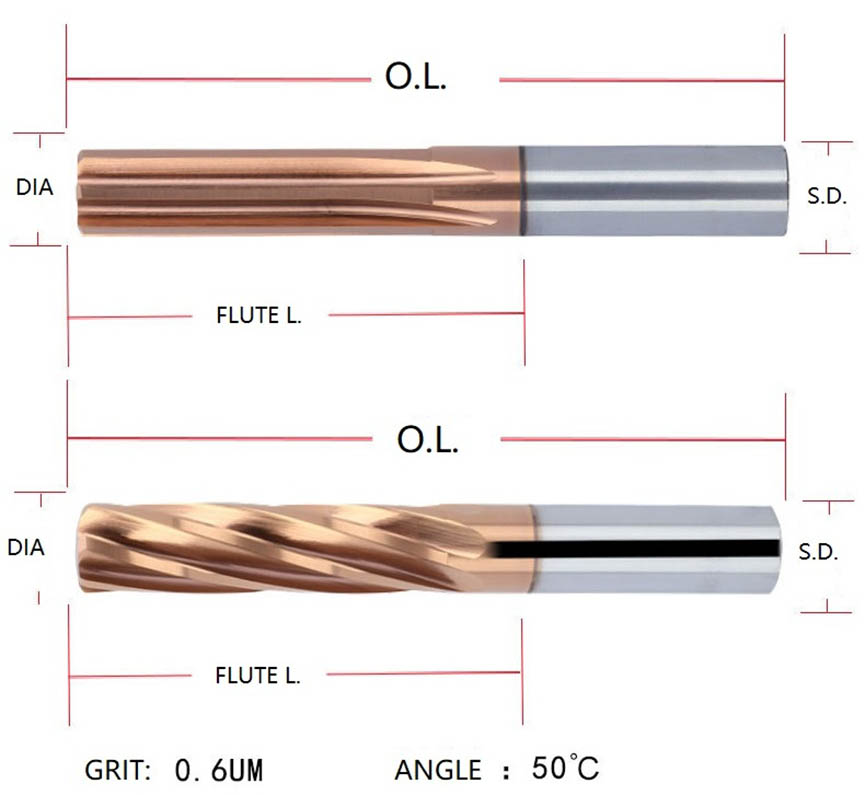

KHOOM PLIG

| DIA | FLUTE L. | SHANK DIA | TSEEM CEEB L. | FLUTES | |

| 3 | 30 | 3D | 60l ua | 4F | |

| 4 | 30 | 4D | 60l ua | 4F | |

| 5 | 30 | 5D | 60l ua | 6F | |

| 6 | 30 | 6D | 60l ua | 6F | |

| 8 | 40 | 8D | 75l ua | 6F | |

| 10 | 45 | 10D | 75l ua | 6F | |

| 12 | 45 | 12D | 75l ua | 6F | |