Preminium Zoo Tungsten Carbide Square End Zeb rau Super Hard Hlau

Nta

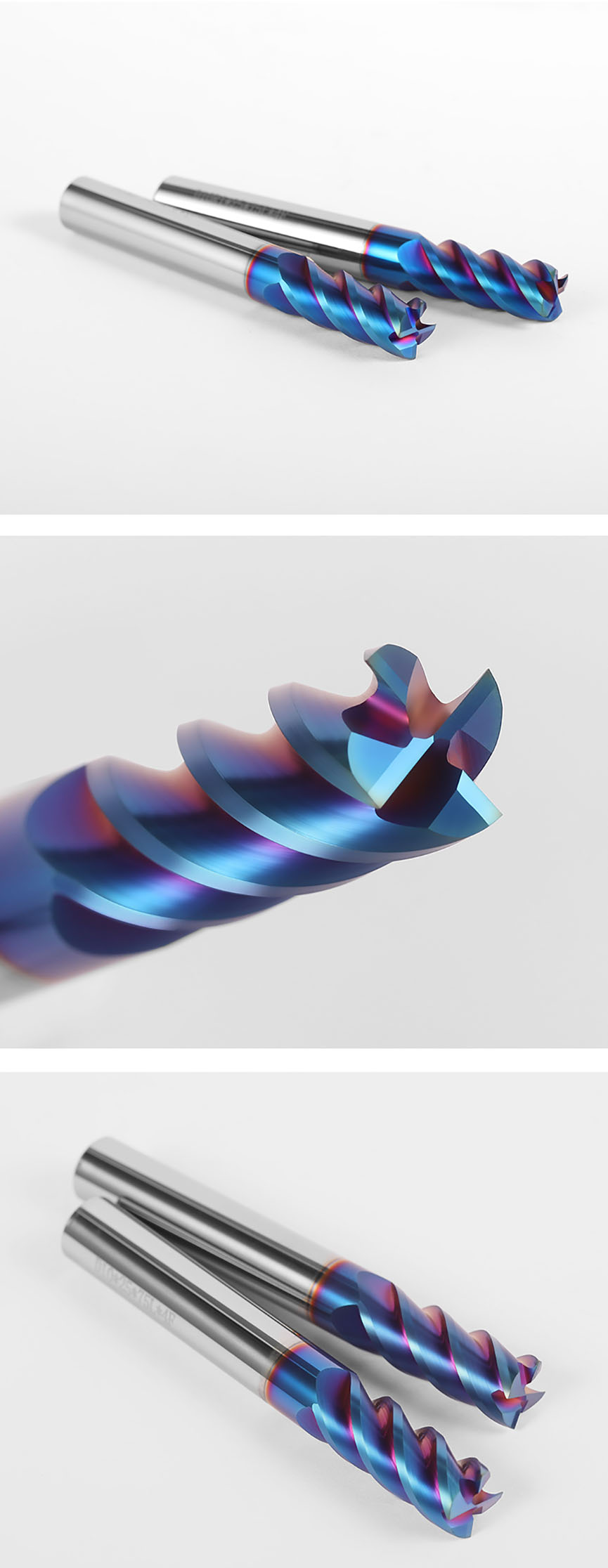

1. Enhanced hardness thiab durability: tungsten carbide khoom siv nyob rau hauv lub kawg zeb muab zoo heev hardness thiab durability, cia nws mus rau high-ceev machining kev khiav hauj lwm thiab ncua sij hawm lub neej.

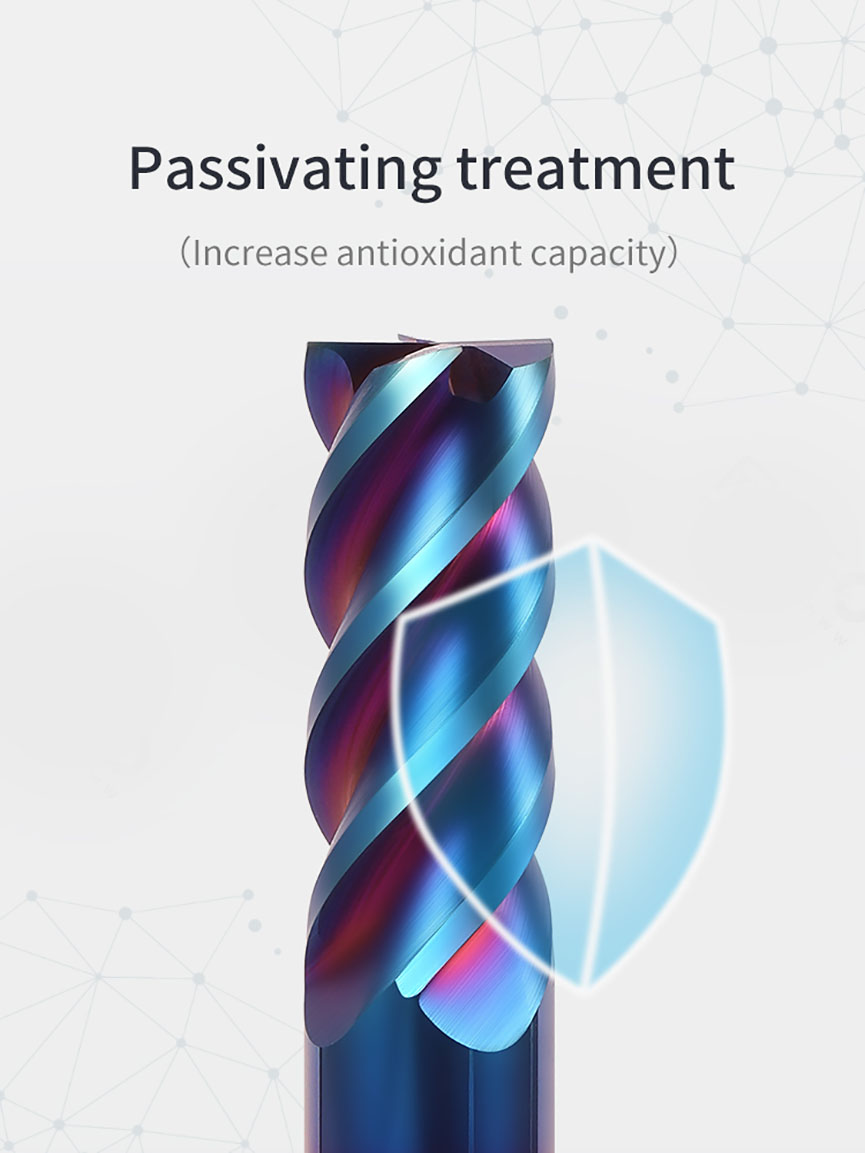

2. Nano xiav txheej: nano xiav txheej yog ib daim nyias nyias, du zaj duab xis siv rau qhov kawg zeb qhov chaw siv cov txheej txheem txheej txheej. Cov txheej no txhim kho cov cuab yeej kev ua tau zoo los ntawm kev txo qis kev sib txhuam thiab kev tsim hluav taws xob thaum txiav, txhim kho nti khiav tawm, thiab tiv taus hnav thiab corrosion.

3. Kev txiav ceev ceev: Lub nano xiav txheej txo qhov kev sib txhuam ntawm qhov kawg zeb thiab cov khoom ua haujlwm, tso cai rau kev txiav nrawm dua. Qhov no ua rau kev txhim kho kev tsim khoom thiab kev ua haujlwm zoo hauv kev ua haujlwm machining.

4. Superior tshav kub tsis kam: Lub nano xiav txheej txhim kho qhov kawg zeb qhov kub tsis kam, ua kom nws tiv taus qhov kub thiab txias tsim thaum txiav. Qhov no txo cov cuab yeej deformation thiab prolongs lub cuab yeej lifespan.

5. Kev hnav zoo heev: Lub nano xiav txheej muab tshwj xeeb hnav tsis kam, txo cov cuab yeej hnav tus nqi thiab ncua nws lub neej kev pab cuam. Qhov no ua rau muaj kev ua tau zoo sib xws thiab txo qis qis rau cov cuab yeej hloov pauv.

6. Txhim kho nti khiav tawm: Lub npoo du ntawm nano xiav txheej txhawb nqa kev khiav tawm ntawm nti zoo dua, tiv thaiv nti tsim thiab txo cov kev pheej hmoo ntawm cov cuab yeej tawg lossis kev puas tsuaj.

7. Precise thiab raug txiav: Kev sib xyaw ua ke ntawm cov khoom siv zoo tungsten carbide thiab nano xiav txheej tso cai rau kev txiav kom raug thiab raug, ua rau kom huv thiab du tiav ntawm lub workpiece.

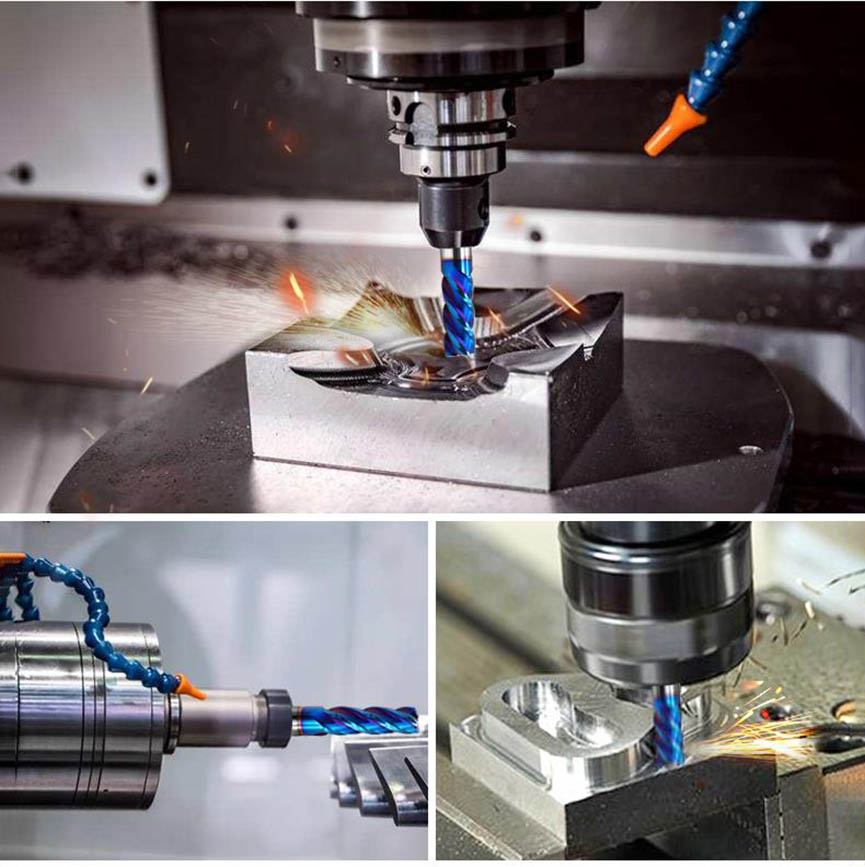

8. Versatility: Tungsten carbide square kawg mills nrog nano xiav txheej tuaj yeem siv rau ntau yam kev ua haujlwm milling, suav nrog roughing, xov, contouring, thiab profileing nyob rau hauv ntau yam ntaub ntawv xws li hlau, stainless hlau, txhuas, thiab lwm yam.

preminium zoo tungsten carbide square kawg zeb nthuav dav

Cov khoom nthuav dav daim duab

Qhov zoo

1. Cov cuab yeej ua kom zoo dua qub: Kev sib xyaw ua ke ntawm cov khoom siv zoo tungsten carbide thiab nano xiav txheej ua rau qhov kawg zeb lub cuab yeej lub neej piv rau cov qauv tsis sib xws. Qhov no ua rau txo cov nqi cuab yeej thiab txhim kho cov khoom tsim tau

2. Txhim kho kev txiav ceev: Lub nano xiav txheej txo kev sib txhuam thiab kev tsim hluav taws xob thaum txiav, tso cai rau kev txiav ntau dua. Qhov no yuav pab txhawb machining efficiency thiab txo lub sij hawm voj voog.

3. Muaj zog hnav tsis kam: Lub nano xiav txheej txhim kho qhov kawg zeb qhov hnav tsis kam, muab kev tiv thaiv kev puas tsuaj thiab txuas ntxiv lub cuab yeej lub neej. Qhov no txhais tau hais tias tsawg dua cov cuab yeej hloov pauv thiab txo qis sijhawm.

4. Superior nto tiav: Lub nano xiav txheej minimizes built-up ntug thiab txo txiav quab yuam, uas ua rau ib tug smoother thiab ntau meej nto tiav ntawm lub workpiece. Qhov no yog qhov tshwj xeeb tshaj yog rau cov ntawv thov uas xav tau qhov zoo ntawm qhov chaw.

5. Chip khiav tawm thiab kev ua kom txias txias: Lub nano xiav txheej txhim kho cov nti ntws thiab cov dej txias, tiv thaiv cov nti txhaws thiab ua kom cov cua sov zoo. Qhov no pab tswj kev ua haujlwm zoo heev thiab txo qhov kev pheej hmoo ntawm cov cuab yeej tsis ua haujlwm.

6. Corrosion tsis kam: Lub nano xiav txheej muab kev tiv thaiv kev tiv thaiv corrosion, txuas rau qhov kawg zeb lub sijhawm ntev thiab txo qis qhov ua tsis tiav ntxov vim yog tshuaj lom neeg degradation.

7. Versatility nyob rau hauv machining daim ntaub ntawv: hwm zoo tungsten carbide square kawg mills nrog ib tug nano xiav txheej yuav siv tau nyob rau hauv ntau yam ntaub ntawv, xws li stainless hlau, hardened steels, cam khwb cia hlau, thiab non-ferrous hlau. Lawv tsim nyog rau roughing, xov, thiab contouring kev ua haujlwm, muab kev yooj yim hauv kev siv machining.

8. Txhim kho cov cuab yeej ruaj khov: Lub nano xiav txheej pab txo qis kev co thiab txhim kho cov cuab yeej ruaj khov thaum txiav, ua rau muaj kev ntseeg siab dua thiab txhim kho qhov tseeb.

9. Cov txiaj ntsig ib puag ncig: Kev siv lub tshuab ua haujlwm siab kawg nrog nano xiav txheej tuaj yeem txo cov kev txiav, xws li txiav quab yuam thiab txiav ceev. Qhov no tuaj yeem ua rau kev txuag hluav taws xob thiab kev siv nyiaj tsawg, ua rau muaj kev ua kom zoo dua qub thiab ruaj khov dua.

| Txoj kab uas hla (mm) | Hniav ntev (mm) | Puv (mm) | Qhov siab (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 ib | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 ib | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 ib | 23 | 75 | 10 |

| 9.5 ib | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 Nws | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 Nws | 30 | 75 | 12 |

| 13.0 Nws | 45 | 100 | 14 |

| 14.0 Nws | 45 | 100 | 14 |

| 15.0 Nws | 45 | 100 | 16 |

| 16.0 Nws | 45 | 100 | 16 |

| 17.0 Nws | 45 | 100 | 18 |

| 18.0 Nws | 45 | 100 | 18 |

| 19.0 Nws | 45 | 100 | 20 |

| 20.0 Nws | 45 | 100 | 20 |

| 22.0 Nws | 45 | 100 | 25 |

| 25.0 Nws | 45 | 100 | 25 |