Phau Ntawv Qhia Qhov Kawg rau Wood Auger Laum Khoom: Precision, Lub Hwjchim, thiab Kev Ua Haujlwm hauv Kev Ua Haujlwm Wood

Ntoo auger laum khoom sawv cev rau lub pinnacle ntawm tshwj xeeb drilling tshuab rau woodworking. Tsis zoo li tus qauv twist me ntsis los yog spade khoom, augers muaj qhov tshwj xeeb muab kauv tsim uas tso cov khib nyiab mus rau pem hauv ntej thaum tsim tshwj xeeb huv, qhov tob nrog kev siv zog tsawg. Los ntawm cov neeg tsim rooj tog mus rau lub qhov rooj, cov kws tshaj lij tso siab rau cov khoom no rau cov haujlwm uas xav tau qhov tseeb hauv qhov tob, txoj kab uas hla, thiab ua tiav-txawm tias tsim cov pob qij txha dowel, khiav thaiv los ntawm kab teeb, lossis txhim kho cylindrical locks.

Core Engineering & Nta

1. Advanced Flute Design & Txiav Geometry

- Multi-Flute Configuration: Hwm auger khoom feature 3-4 helical flutes (grooves) uas ua zoo li conveyor systems, zoo ejecting ntoo chips upward. Qhov no tiv thaiv kev txhaws hauv qhov tob (txog 300-400 mm) thiab txo cov cua sov. Ib leeg-flute designs suits softer woods, thaum 4-flute variants zoo nyob rau hauv hardwoods los yog resinous ntoo.

- Screw Tip Pilot: Ib qho kev pub mis rau tus kheej ntawm lub taub hau rub lub ntsis mus rau hauv cov ntoo, tshem tawm kev taug kev thiab ua kom lub qhov raug qhov tseeb ntawm thawj qhov kev hloov pauv. Qhov no contrasts nrog spade khoom, uas yuav tsum tau ruaj siab thiab feem ntau drift off-kos npe.

- Spur Cutters: Muab cov npoo ntawm qhov me me periphery hlais ntoo fibers kom huv si ua ntej lub cev tseem ceeb nqa cov khoom, ua rau tsis muaj kev nkag mus thiab tawm qhov - qhov tseem ceeb rau kev pom kev sib koom ua ke.

2. Shank Engineering rau Lub Hwj Chim & Compatibility

- Hex Shank Dominance: Tshaj 80% ntawm cov augers niaj hnub siv 6.35mm (1/4 ") lossis 9.5mm (3/8") hex shanks. Cov xauv no ruaj ntseg rau hauv cov chucks hloov ceev (xws li, cuam tshuam cov tsav tsheb) thiab tiv thaiv kev poob qis hauv qhov siab torque. SDS thiab round shanks tseem yog cov kev xaiv tshwj xeeb rau cov khoom siv tshwj xeeb.

- Reinforced Collar: Cov qauv kev ntxhov siab muaj xws li cov dab tshos tuab tuab hauv qab ntawm lub shank, tiv thaiv flex thaum lub sij hawm hnyav drilling hauv ntom ntoo qhib lossis maple.

3. Material Science: Los ntawm HSS mus rau Carbide

- High-Speed Steel (HSS): Cov qauv kev lag luam rau kev sib npaug ntawm cov nqi thiab kav ntev. Khaws qhov tob tob txog 350 ° C thiab tiv taus 2-3x rov ua dua tshiab. Zoo tagnrho rau cov kws ntoo dav dav.

- High-Carbon Steel: Harder dua HSS tab sis nkig ntau dua. Qhov zoo tshaj plaws rau high-volume softwood drilling qhov twg ntug tuav outweighs feem cuam tshuam.

- Carbide-Tipped: nta brazed tungsten carbide txiav npoo rau drilling abrasive composites, laminated ntoo, los yog khov ntoo. Ntev 5-8x ntev dua HSS tab sis ntawm 3x tus nqi hwm.

Cov lus: Auger ntsis khoom sib piv

| Hom khoom | Zoo tshaj rau | Drilling Life | Nqi Factor |

|---|---|---|---|

| High-Carbon Steel | Softwoods, ua haujlwm siab | Nruab nrab | $ |

| High Speed Steel (HSS) | Hardwoods, sib xyaw cov ntaub ntawv | Siab | $$ |

| Carbide-Tip | Composites, abrasive ntoo | Siab heev | $$$$ |

Technical Advantages Tshaj Cov Khoom Siv

- Lub peev xwm tob: Augers laum txog li 10x lawv txoj kab uas hla tob (xws li, 40mm ntsis → 400mm qhov tob) yam tsis muaj kev khi-tsis sib haum los ntawm Forstner lossis spade khoom.

- Ceev & Efficiency: Lub hau ntsia hlau rub lub ntsis ntawm 2-3x pub tus nqi ntawm kev sib tw twist, txiav 25mm-qhov tob hauv cov ntoo hauv qis dua 5 vib nas this nrog 1,000 RPM xyaum.

- Precision Tolerances: Industrial-qib cov khoom (xws li ISO9001-certified) tuav diameters nyob rau hauv ± 0.1mm, tseem ceeb heev rau dowel pins los yog xauv installation. Cov khoom tsis sib xws (piv txwv li, 1 "ntsis nrog 7/8" twist) ua tsis tiav hauv kev coj ua jigs, thaum qhov tseeb 1: 1 piv cov khoom ua tiav.

- Chip Clearance: Flutes khiav tawm 95% + ntawm cov khib nyiab, txo kev sib txhuam thiab tiv thaiv "siav ntoo" scorching hauv qhov tob tshaj 150mm.

Technical Specifications & Kev Taw Qhia Kev Xaiv

Sizing Standards

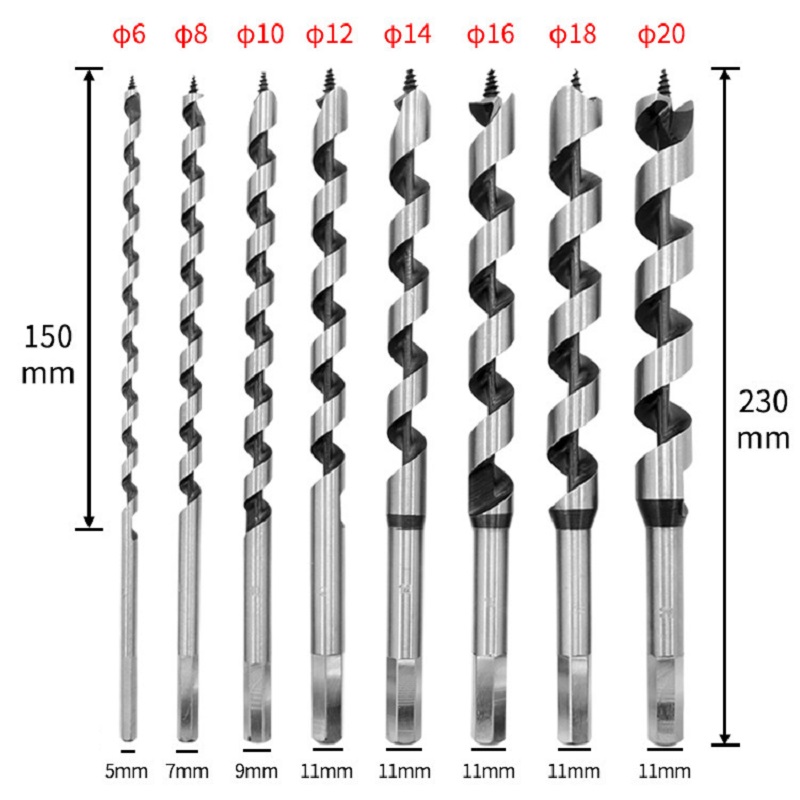

- Txoj kab uas hla: 5mm-100mm (ua haujlwm tshwj xeeb):

- 6-10mm: Doweling, hluav taws xob conduits

- 15-40mm: Xauv lub tog raj kheej, cov kav dej

- 50-100mm: Cov kab teeb pom kev zoo, qhov loj-inch joinery

- Cov chav kawm ntev:

- Luv (90-160mm): Cabinetry, qhov rooj latch qhov

- Ntev (300-400mm): Ntoo thav duab, sib sib zog nqus mortises

Coatings & Surface Treatments

- Dub Oxide: Txo kev sib txhuam los ntawm 20% thiab ntxiv cov tshuaj tiv thaiv corrosion. Txheem rau HSS khoom.

- Bright Polished: Smooth nto minimizes resin adhesion nyob rau hauv ntoo thuv los yog cedar. Muaj nyob rau hauv daim ntawv thov kev nyab xeeb zaub mov.

- Titanium Nitride (TiN): Kub-xim txheej rau 4x hnav tsis kam; tsis tshua muaj nyob rau hauv augers vim nqi.

Cov lus: Shank Hom & Compatibility

| Hom Shank | Tool Compatibility | Torque tuav | Siv Case |

|---|---|---|---|

| Hex (6.35 hli / 9.5mm) | Impact tsav tsheb, ceev-chuck xyaum | Siab | Kev tsim kho dav dav |

| Hloov | Traditional braces, tes xyaum | Nruab nrab | Kev ua haujlwm zoo ntawm ntoo |

| SDS-Plus | Rotary rauj | Siab heev | Drilling rau hauv ntoo nrog embedded ntsia hlau |

Real-World Applications & Pro Tips

- Kev Txhim Kho Qhov Rooj Xauv: Siv 1 "inch augers (nrog qhov tseeb 1" twist) rau lub qhov latch. Tsis txhob spade me ntsis - lawv rhuav tshem cov npoo mortise thiab sib txawv hauv qhov sib sib zog nqus .

- Kev Tsim Kho Vaj Tse: Pair 12 "-16" ntev 32mm augers nrog kev xyaum ua haujlwm siab (≥650 Nm) rau railing posts lossis beam joinery. Ntxiv paraffin wax rau flutes thaum drilling resinous ntoo.

- Furniture Ua: Rau cov pob qij txha dowel, xaiv cov khoom 0.1mm wider dua dowels kom tso cov nplaum nthuav.

Quality Assurance & Certifications

Cov tuam txhab lag luam saum toj kawg nkaus ua raws li ISO 9001 cov qauv, kev siv lub zog hardness (HRC 62-65 rau HSS), qhov tseeb qhov tseeb, thiab kev ntsuas kev thauj khoom. Cov khoom raug kuaj xyuas kev puas tsuaj los xyuas kom muaj zog torsional tshaj 50 Nm.

Xaus: Qhov Indispensable Woodworking Workhorse

Ntoo auger laum khoom sib koom ua ke centuries-laus cov txheej txheem kev siv tshuab nrog niaj hnub metallurgy. Lawv optimized nti khiav tawm, qhov tob muaj peev xwm, thiab precision ua rau lawv irreplaceable rau cov tub txawg uas muaj nuj nqis ceev yam tsis muaj kev txi zoo. Thaum xaiv me ntsis, ua qhov tseem ceeb tshaj plaws HSS lossis carbide-tipped qauv nrog hex shanks thiab ntau-flute designs - kev nqis peev uas them rov qab rau lawv tus kheej hauv cov txiaj ntsig tsis zoo thiab txo qis kev cob qhia.

Post lub sij hawm: Lub Xya hli ntuj-26-2025