Phau Ntawv Qhia Qhov Kawg rau Pob Zeb Diamond Core Khoom: Revolutionizing Precision Drilling Technology

Hom thiab Classifications ntawm Pob Zeb Diamond Core Khoom

Hom thiab Classifications ntawm Pob Zeb Diamond Core Khoom

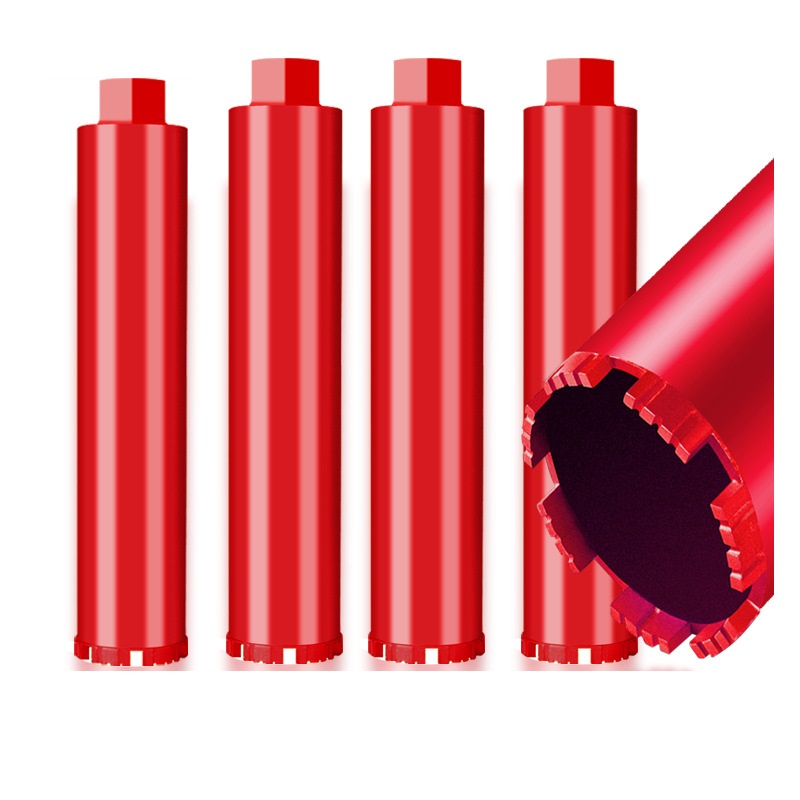

Pob zeb diamond core khoom tuaj nyob rau hauv ntau yam kev teeb tsa, txhua tus tsim los daws cov kev sib tw tshwj xeeb thiab cov khoom siv. Nkag siab txog cov kev faib tawm no yog qhov tseem ceeb rau kev xaiv qhov tsim nyog me ntsis rau txhua daim ntawv thov.

Qhuav vs. ntub pob zeb diamond Core khoom

Ib qho ntawm cov kev sib txawv hauv cov pob zeb diamond tseem ceeb yog nyob rau hauv lawv cov txheej txheem txias. Cov khoom siv pob zeb qhuav qhuav, xws li CorePlus CORDCDKIT7 teeb, yog tsim los rau kev ua haujlwm uas cov dej txias tsis zoo los yog tsis xav tau 1. Cov khoom no feem ntau muaj cov ribbed core lub cev thiab V-groove ntu uas ua kom nrawm nrawm ntawm cov khib nyiab, tso cai rau kev txiav txiav txuas ntxiv. Lub aerated core tsim ua kom txias txias thiab txuas ntxiv lub neej tseem ceeb, ua rau lawv zoo tagnrho rau cov xwm txheej overhead drilling los yog cov khoom siv dej-rhiab heev.

Cov pob zeb diamond ntub dej, ntawm qhov tod tes, xav tau dej txias thaum lub sijhawm ua haujlwm los tiv thaiv overheating thiab txuas lub neej ntawm lub ntsis. Cov khoom no, xws li 25-102mm laser-welded ntub pob zeb diamond tub ntxhais cov khoom, tshwj xeeb tshaj yog engineered rau reinforced pob zeb drilling thiab muaj superior txias peev xwm uas tso cai rau kom tob thiab ceev nkag mus rau hauv cov ntaub ntawv tawv 8. Cov dej ua hauj lwm ob qho tib si raws li ib tug coolant thiab raws li ib tug txhais tau tias kom yaug tawm drilling khib nyiab, tswj kev txiav efficiency thoob plaws hauv lub lag luam.

Impregnated vs. Nto-Teeb khoom

Lwm qhov kev faib tawm tseem ceeb txawv ntawm impregnated thiab nto-set pob zeb diamond core khoom. Impregnated khoom feature pob zeb diamond faib thoob plaws hauv matrix ntawm me ntsis, xws li 61.5mm impregnated pob zeb diamond core ntsis tsim rau granite nyuaj pob zeb drilling 6. Raws li cov matrix hnav thaum lub sijhawm ua haujlwm, cov pob zeb diamond tshiab tau nthuav tawm tsis tu ncua, tswj qhov kev txiav me me ntawm lub sijhawm ntev.

Cov khoom ntog muaj cov pob zeb diamond nthuav tawm ntawm qhov chaw ntawm matrix, muab kev txiav txim siab zoo rau cov ntaub ntawv softer. Cov khoom no feem ntau muab kev txiav nrawm dua tab sis tuaj yeem hnav sai dua li cov qauv tsim hauv cov ntawv thov abrasive.

Tshwj xeeb tsim ntau yam

Ntau yam tshwj xeeb pob zeb diamond core me ntsis tsim tau tshwm sim los daws cov teeb meem tshwj xeeb drilling:

- PDC (Polycrystalline Pob Zeb Diamond Compact) cov khoom: Cov khoom no, uas muaj cov khoom siv hluav taws xob hluavtaws, yog siv dav hauv kev tshawb nrhiav roj thiab roj nrog rau cov qauv geological core 3. Lawv muaj qhov tshwj xeeb durability thiab txiav efficiency nyob rau hauv ob qho tib si mos thiab nruab nrab-nyuaj formations.

- Concave pob zeb diamond cov khoom siv: Cov qauv tsim tshiab zoo li StrataBlade cov khoom siv zog tshwj xeeb geometry cutters nrog cov yam ntxwv sib txawv uas txo qhov zoo ntawm cov cutter back-rake lub kaum sab xis, ua kom tob txiav rau hauv abrasive thiab cuam tshuam pob zeb.

- Cov pob zeb tshwj xeeb: Cov pob zeb diamond tshwj xeeb zoo li Würth Pob Zeb Diamond pobzeb qhuav core ntsis M14 lub rooj yog tsim tshwj xeeb rau kev drilling los ntawm cov khoom siv tawv tawv heev uas tsis muaj dej txias.

Technical Specifications thiab Design Features

Pob zeb diamond core cov khoom sib txuas nrog kev tsim kho tshiab thiab cov qauv tsim khoom kom paub meej tias kev ua haujlwm zoo thoob plaws ntau yam kev siv. Nkag siab txog lawv cov kev qhia tshwj xeeb yog qhov tseem ceeb rau kev xaiv kom raug thiab siv tau.

Pob zeb diamond zoo thiab siab

Qhov kev ua tau zoo ntawm pob zeb diamond core me ntsis feem ntau nyob ntawm qhov zoo thiab qhov siab ntawm cov pob zeb diamond siv hauv nws qhov kev tsim kho. Cov pob zeb diamond muaj qib yog ua tib zoo xaiv raws li qhov loj me, cov duab, thiab cov yam ntxwv ntawm lub zog kom phim cov kev xav tau tshwj xeeb drilling. Raws li DZ / T 0277-2015 tus qauv rau geological core drilling pob zeb diamond khoom, cov tuam ntxhab yuav tsum ua raws li cov lus qhia nruj txog pob zeb diamond zoo thiab kev faib tawm kom ntseeg tau tias kev ua haujlwm zoo ib yam.

Matrix Composition

Lub matrix, los yog cov hlau alloy uas tuav cov pob zeb diamond nyob rau hauv qhov chaw, plays lub luag haujlwm tseem ceeb hauv kev txiav txim siab me ntsis cov yam ntxwv ua haujlwm. Lub matrix yuav tsum tau tsim kho kom hnav ntawm tus nqi tswj uas tsis tu ncua nthuav tawm cov pob zeb diamond tshiab thaum tuav cov qauv kev ncaj ncees. Sib txawv matrix compositions yog tsim los rau tej hom kev tsim:

- Mos formation matrices: Softer daim ntawv cog lus cov ntaub ntawv uas hnav sai dua, kom ntseeg tau tias pob zeb diamond raug nyob rau hauv tsawg abrasive formations.

- Hard formation matrices: Harder, ntau hnav-resistant bonds uas tiv thaiv pob zeb diamond retention nyob rau hauv abrasive ib puag ncig.

- Medium formation matrices: Balanced formulations uas muab kev ua tau zoo hauv kev sib xyaw ua ke.

Me ntsis tsim thiab Geometry

Lub cev tsim ntawm pob zeb diamond core me ntsis cuam tshuam rau lawv qhov kev ua tau zoo:

Cov lus: Pob zeb diamond Core ntsis tsim nta thiab lawv cov haujlwm

| Tsim Feature | Muaj nuj nqi | Piv txwv daim ntawv thov |

|---|---|---|

| Dej Channel | Cia coolant ntws mus rau qhov chaw txiav | Txhua daim ntaub ntub dej drilling |

| Ntu Qhov siab | Txiav txim me ntsis lub neej thiab hnav tsis kam | Ntev drilling tej yaam num |

| Ntu Qauv | Muaj feem xyuam rau kev txiav ceev thiab kev tshem tawm cov khib nyiab | Kev ua haujlwm ceev ceev |

| Xov Hom | Ua kom muaj kev sib raug zoo nrog cov khoom siv drilling | Standardized drilling kev teeb tsa |

| Ntu dav | Influences stability thiab txiav aggression | Precision drilling xav tau |

Husqvarna VARI-DRILL D25 DRY series qhia tau hais tias yuav ua li cas sophisticated tsim nta txhim khu kev ua tau zoo, nrog rau tej ntu configurations (3-4mm thickness, 9mm qhov siab) optimized rau ntau yam pob zeb.

Loj Specifications

Pob zeb diamond core cov khoom muaj nyob rau hauv ntau qhov ntau thiab tsawg los ua kom haum rau cov kev xav tau sib txawv. Qhov ntau thiab tsawg ntawm cov kab me me (raws li me me li 1 nti / 25mm rau kev ua haujlwm precision) 4 mus rau txoj kab uas hla loj tshaj li 200mm rau kev tsim kho loj 7. Tus qauv DZ/T 0277-2015 qhia meej meej qhov ntev ntev rau geological drilling cov khoom, ua kom haum thiab ua haujlwm hauv kev ua haujlwm.

Qhov zoo thiab txiaj ntsig ntawm Pob Zeb Diamond Core Khoom

Lub superiority ntawm pob zeb diamond core me ntsis tshaj cov pa drilling technologies manifests nyob rau hauv ntau yam ntawm drilling ua hauj lwm, muab tangible txiaj ntsim rau cov tub txawg nyob rau hauv industries.

Exceptional txiav efficiency thiab ceev

Pob zeb diamond tseem ceeb cov khoom muaj qhov nkag tau nrawm dua piv rau cov khoom siv sib xyaw ua ke, tshwj xeeb tshaj yog cov khoom siv tawv thiab cov khoom abrasive. StrataBlade concave pob zeb diamond cov khoom, piv txwv li, tau ua kom pom txog li 28% nce ntawm tus nqi nkag (ROP) piv rau cov khoom siv hauv kev sim teb ua nyob rau hauv Haynesville Basin 10. Qhov kev txhim kho kev ua tau zoo no txhais tau ncaj qha rau hauv kev txo cov sij hawm drilling thiab txo nqi zog rau ib qhov project.

Precision thiab zoo ntawm kev txiav

Qhov tshwj xeeb txiav txiav ntawm pob zeb diamond core khoom ua kom huv si, qhov tseeb nrog qhov tsawg kawg nkaus los yog cov khoom puas tsuaj. Qhov kev txiav txim siab no yog qhov tseem ceeb tshwj xeeb hauv cov ntawv thov uas qhov tseeb qhov geometry thiab cov phab ntsa du yog qhov tseem ceeb, xws li hauv cov kav dej, hluav taws xob, thiab HVAC kev teeb tsa hauv kev tsim kho. Cov khoom tshwj xeeb xws li Würth Pob Zeb Diamond pobzeb qhuav core me ntsis yog tsim tshwj xeeb los tiv thaiv kev puas tsuaj rau cov khoom siv zoo li cov vuas luaj ceramic thaum xa cov qhov huv si zoo kawg nkaus.

Longevity thiab nqi-zoo

Txawm hais tias lawv cov nqi pib siab dua, pob zeb diamond tseem ceeb cov khoom muaj qhov tshwj xeeb rau lub sijhawm ntev los ntawm kev pabcuam lub neej ntev thiab txo qhov hloov zaus. Lub impregnated pob zeb diamond core khoom tsim los ntawm cov tuam txhab xws li Hunan Diyfia yog tsim los tsis tu ncua nthuav tawm cov pob zeb diamond tshiab raws li cov matrix hnav, tswj kev txiav kev ua haujlwm thoob plaws hauv lub neej 6. Qhov kev ua haujlwm ntev no ua rau lawv tus nqi tshwj xeeb rau kev ua haujlwm loj drilling uas nquag hloov me ntsis yuav cuam tshuam rau kev tsim khoom.

Versatility hla cov ntaub ntawv

Pob zeb diamond tseem ceeb cov khoom ua tau zoo tshaj plaws versatility, muaj peev xwm ntawm drilling los ntawm ntau yam khoom siv xws li:

- Qhob thiab reinforced pob zeb: Standard daim ntawv thov nyob rau hauv kev tsim kho

- Ntuj pob zeb thiab masonry: suav nrog granite, marble, thiab limestone

- Ceramic thiab porcelain vuas: Cov khoom tshwj xeeb qhuav tiv thaiv kev tawg

- Asphalt thiab cov ntaub ntawv sib xyaw: Nrog cov qauv tsim tshwj xeeb

- Geological formations: Rau core sampling hauv kev tshawb nrhiav

Txo tus neeg ua haujlwm qaug zog

Qhov kev txiav txim siab zoo ntawm cov pob zeb diamond tseem ceeb yuav tsum tau qis qis qis dua thiab ua kom muaj kev vibration tsawg dua piv rau cov qauv kev drilling. Qhov kev txo qis hauv lub cev no txhais tau tias txo qis tus neeg ua haujlwm qaug zog, tshwj xeeb yog qhov tseem ceeb thaum lub sijhawm ua haujlwm txuas ntxiv lossis thaum ua haujlwm nyiaj siv ua haujlwm. Kev txhim kho ergonomics ua rau muaj txiaj ntsig zoo dua thiab txhim kho qhov chaw ua haujlwm nyab xeeb.

Kev siv thiab siv pob zeb diamond Core khoom

Pob zeb diamond tseem ceeb cov khoom ua haujlwm tseem ceeb hauv kev lag luam sib txawv, txhua tus muaj cov kev cai tshwj xeeb uas siv cov peev txheej tshwj xeeb ntawm cov cuab yeej siab heev.

Kev tsim kho thiab kev tsim vaj tsev

Hauv kev tsim kho, cov pob zeb diamond tseem ceeb yog qhov tseem ceeb rau kev tsim cov qhov qhib meej rau kev siv hluav taws xob, HVAC systems, kav dej, thiab cov kav dej hluav taws xob. Lawv lub peev xwm los txiav los ntawm cov pob zeb uas tsis muaj kev puas tsuaj rau cov qauv kev ncaj ncees ntawm cov khoom nyob ib puag ncig ua rau lawv muaj txiaj ntsig tshwj xeeb rau kev kho dua tshiab thiab rov tsim dua tshiab. Lub 25-102mm laser-welded ntub pob zeb diamond core khoom ua piv txwv cov cuab yeej tshwj xeeb tsim rau cov ntawv thov no, muab kev kub ceev drilling nrog cov txiaj ntsig huv hauv cov pob zeb thiab cov pob zeb ntxiv.

Kev lag luam roj thiab roj

Kev lag luam roj av cia siab ntau rau cov pob zeb diamond core ntsis thev naus laus zis rau kev tshawb nrhiav thiab kev tsim khoom drilling. PDC cov khoom tau dhau los ua ntau dua hauv cov ntawv thov roj av vim lawv qhov ua tau zoo dua qub thiab kev ua haujlwm zoo dua piv rau cov khoom siv rau cov menyuam lub khob hliav qab. Kev tsim kho tshiab tsis ntev los no zoo li StrataBlade concave pob zeb diamond cov khoom tau pom tias muaj kev txhim kho tseem ceeb hauv kev ua haujlwm drilling, nrog rau kev ntsuam xyuas thoob plaws hauv cov pob zeb loj loj uas qhia txog kev txhim kho ROP.

Cov ntawv thov tshwj xeeb

Tshaj li cov kev lag luam loj no, cov pob zeb diamond tseem ceeb ua haujlwm rau ntau yam tshwj xeeb:

- Kev tsim khoom semiconductor: Kev txhim kho ntawm 100mm ib leeg-crystal pob zeb diamond wafers sawv cev rau kev ua tiav uas tuaj yeem hloov pauv kev tswj xyuas thermal hauv cov hluav taws xob hluav taws xob siab 9. Txawm hais tias tsis yog daim ntawv thov drilling ib se, qhov kev tsim kho tshiab no qhia txog kev nthuav dav ntawm pob zeb diamond technology.

- Pobzeb thiab masonry ua hauj lwm: Cov pob zeb diamond tshwj xeeb cov khoom zoo li Würth M14 series pab cov kws tshaj lij los tsim qhov zoo tshaj plaws hauv cov khoom siv ceramic uas tsis muaj dej txias, tiv thaiv kev puas tsuaj rau qhov chaw tiav.

- Kev tsim kho vaj tse: Loj-inch pob zeb diamond core me me yog qhov tseem ceeb rau kev tsim qhib rau cov khoom siv hluav taws xob, cov kav dej, thiab cov ntsiab lus nkag hauv cov phiaj xwm loj.

Cov Lus Qhia Xaiv thiab Cov Lus Qhia Siv

Xaiv qhov tsim nyog pob zeb diamond core me ntsis rau ib daim ntawv thov tshwj xeeb yuav tsum tau ua tib zoo xav txog ntau yam los xyuas kom meej qhov kev ua tau zoo thiab tus nqi zoo.

Kev ntsuam xyuas cov khoom sib xws

Thawj kauj ruam hauv kev xaiv lub pob zeb diamond core me ntsis suav nrog kev txheeb xyuas cov khoom tseem ceeb uas yuav tsum tau drilled. Cov ntaub ntawv sib txawv xav tau cov qauv tsim tshwj xeeb thiab pob zeb diamond configuration:

- Mos pob zeb thiab cib: Cov txheej txheem txheej txheej txheej nrog pob zeb diamond raug pom ntau dua

- Reinforced qhob: Hard-bonded khoom nrog kub tsis kam rau steel reinforcement

- Abrasive sandstone: Impregnated khoom nrog cov qauv matrix ruaj khov

- Ceramic thiab porcelain: Fine-grit pob zeb diamond hais nrog tshwj xeeb ntu tsim

Cov khoom siv Compatibility Check

Ua kom muaj kev sib raug zoo ntawm pob zeb diamond core ntsis thiab cov khoom siv drilling yog qhov tseem ceeb rau kev nyab xeeb thiab kev ua haujlwm. Cov ntsiab lus tseem ceeb suav nrog:

- Xov hom compatibility: Standard kev sib txuas muaj xws li 1/2 "BSP, M14, M16, thiab 5/8"-11 xov 18

- Cov khoom siv hluav taws xob xav tau: Ua kom muaj peev xwm txaus torque thiab RPM

- Txias system compatibility: Muab cov khoom ntub / qhuav nrog cov khoom tsim nyog

Kev ua haujlwm zoo tshaj plaws

Kev ua haujlwm kom raug txuas ntxiv me ntsis lub neej thiab ua kom pom kev ua haujlwm zoo:

- Kev ua kom txias txaus: Khaws cov dej kom zoo rau cov khoom ntub dej los yog qhov tsim nyog drilling ncua sij hawm rau cov khoom qhuav

- Qhov zoo tshaj plaws siab: Siv lub siab txaus rau kev txiav kom zoo yam tsis muaj kev quab yuam ntau dhau uas ua rau muaj cua sov

- Kev tu tsis tu ncua: tshem cov khib nyiab ntawm qhov thiab cov ntu me me kom tsis txhob txhaws

- Kev hloov ceev: Hloov RPM raws li cov khoom hardness thiab me ntsis txoj kab uas hla

Kev tu thiab khaws cia

Kev saib xyuas kom zoo txuas ntxiv pob zeb diamond tseem ceeb lub neej thiab tswj kev ua haujlwm:

- Ua kom huv huv tom qab siv txhua qhov kom tshem tawm cov khib nyiab ntawm ntu

- Kev khaws cia hauv cov ntaub ntawv tiv thaiv kom tsis txhob muaj pob zeb diamond puas

- Kev tshuaj xyuas tsis tu ncua rau ntu hnav lossis puas tsuaj ua ntej siv

- Cov txheej txheem ntse rau cov khoom impregnated thaum txiav kev ua haujlwm qis

Innovations thiab yav tom ntej Trends nyob rau hauv pob zeb diamond Core ntsis Technology

Lub pob zeb diamond tseem ceeb ntawm kev lag luam txuas ntxiv mus, nrog kev tshawb fawb thiab kev txhim kho txuas ntxiv tsom mus rau kev txhim kho kev ua tau zoo, nthuav cov ntawv thov, thiab txo cov nqi.

Advanced Materials thiab Manufacturing

Kev nce qib tsis ntev los no hauv cov ntaub ntawv tshawb fawb tau ua rau muaj kev txhim kho tseem ceeb hauv pob zeb diamond core ntsis thev naus laus zis. Txoj kev loj hlob ntawm premium-qib hluavtaws pob zeb diamond nrog ua tib zoo tswj cov khoom tau ua rau cov tuam txhab ua kom zoo dua pob zeb diamond concentration thiab faib rau cov ntawv thov tshwj xeeb. Tsis tas li ntawd, kev tsim kho tshiab hauv metallurgy thiab pob zeb diamond / hlau sib txuas cov tswv yim tau ua rau cov ntaub ntawv matrix ruaj khov uas txuas ntxiv me ntsis lub neej hauv cov qauv nyuaj.

Tshwj xeeb Geometry thiab Hydraulic

Cov tuam txhab me me tau tsom mus rau kev tsim kho hydraulic zoo uas txhim kho cov cua txias thiab cov khib nyiab tshem tawm, txhim kho ob qho tib si drilling efficiency thiab me ntsis lub neej. Lub StrataBlade concave pob zeb diamond cov khoom nrog lawv cov cim geometry sawv cev rau cov qauv no, uas muaj qhov tshwj xeeb concave tsim uas txo qhov zoo cutter back-rake lub kaum sab xis rau kev nkag mus tob dua 10. Ib yam li ntawd, CorePlus Pob Zeb Diamond Dry Core Laum Bit suav nrog lub ribbed core lub cev thiab V-groove ua kom nrawm nrawm rau kev txiav txim siab ceev ceev.

Kev koom ua ke nrog Digital Technologies

Lub neej yav tom ntej ntawm pob zeb diamond core ntsis thev naus laus zis suav nrog kev sib koom ua ke ntau dua nrog cov tshuab digital rau kev saib xyuas thiab kev tswj xyuas. Ntse drilling tshuab uas kho qhov tsis sib xws hauv lub sijhawm tiag tiag raws li kev tawm tswv yim tsim tau dhau los ua ntau dua, tshwj xeeb hauv kev siv roj thiab roj. Cov tshuab no ua kom zoo dua me ntsis kev ua tau zoo thiab tiv thaiv kev puas tsuaj los ntawm kev hloov pauv hloov cov yam ntxwv thaum lub sijhawm ua haujlwm drilling.

Environmental thiab Efficiency Considerations

Kev loj hlob tseem ceeb ntawm kev ruaj khov yog tsav kev tsim kho tshiab hauv kev siv hluav taws xob zoo drilling technologies. Cov pob zeb diamond tseem ceeb pab txhawb rau cov hom phiaj no los ntawm kev txo lub sijhawm drilling thiab qis zog siv piv rau cov qauv siv. Tsis tas li ntawd, txoj kev loj hlob ntawm cov tshuab drilling qhuav uas tshem tawm cov dej siv tau hais txog kev txhawj xeeb ntawm ib puag ncig hauv cov dej-rhiab heev thaum tswj kev ua haujlwm drilling.

Xaus: Lub neej yav tom ntej ntawm Drilling nrog Pob Zeb Diamond Core khoom

Pob zeb diamond tseem ceeb cov khoom tau tsim lawv tus kheej ua cov cuab yeej tseem ceeb hauv kev lag luam ntau, muab kev ua haujlwm tsis sib xws hauv kev drilling los ntawm cov ntaub ntawv nyuaj. Los ntawm kev tsim kho thiab mining mus rau cov ntawv tshwj xeeb hauv kev tsim khoom semiconductor, cov cuab yeej txiav qib siab no txuas ntxiv hloov zuj zus los ntawm kev tsim kho tshiab hauv cov ntaub ntawv, tsim, thiab kev tsim khoom.

Lub neej yav tom ntej ntawm pob zeb diamond core ntsis thev naus laus zis tau cog lus ntau dua qhov ua tau zoo, kev ua tau zoo, thiab ntau yam raws li cov tuam txhab koom nrog kev nkag siab los ntawm cov ntaub ntawv tshawb fawb, thev naus laus zis digital, thiab kev tsim kho qib siab. Kev txhim kho tsis tu ncua ntawm cov khoom tshwj xeeb rau cov ntawv thov tshwj xeeb, ua ke nrog kev txhim kho pob zeb diamond zoo thiab matrix formulations, yuav nthuav ntxiv cov peev txheej ntawm cov cuab yeej zoo kawg no.

Raws li kev txhim kho thoob ntiaj teb kev txhim kho txuas ntxiv thiab kev tshawb nrhiav rau cov peev txheej txav mus rau hauv ib puag ncig nyuaj, qhov tseem ceeb ntawm pob zeb diamond core ntsis thev naus laus zis tsuas yog nce ntxiv. Cov kws tshaj lij thoob plaws kev lag luam tuaj yeem cia siab tias yuav pom cov kev nce qib txuas ntxiv uas txhim kho kev ua haujlwm drilling, txo cov nqi khiav lag luam, thiab ua kom cov ntawv thov tshiab uas tam sim no dhau ntawm peb lub peev xwm.

Txawm hais tias tsim kom muaj qhov qhib qhib rau hauv cov pob zeb ua kom muaj zog, tau txais cov qauv qauv los ntawm qhov tob hauv qab lub ntiaj teb saum npoo av, lossis ua kom muaj kev cuam tshuam hauv kev tswj hwm hluav taws xob hluav taws xob, cov pob zeb diamond tseem ceeb yuav txuas ntxiv mus ua lub luag haujlwm tseem ceeb hauv kev tsim peb qhov chaw tsim thiab nthuav peb txoj kev nkag siab ntawm lub ntiaj teb ntuj.

Post lub sij hawm: Aug-31-2025