Morse Taper Shank HSS kawg Mills

Nta

1. Morse Taper Shank: Qhov kawg zeb muaj lub shank uas yog tsim kom haum rau hauv Morse Taper spindle. Morse Taper system tso cai rau kev ruaj ntseg thiab raug mounting ntawm qhov kawg zeb hauv lub tshuab milling.

2. High-Speed Steel (HSS): HSS yog ib hom cuab yeej steel feem ntau siv hauv cov cuab yeej txiav. HSS kawg mills paub txog lawv qhov toughness, kub tsis kam, thiab muaj peev xwm tiv taus siab txiav ceev. HSS kawg mills yog tsim rau ntau yam ntaub ntawv, xws li carbon steel, alloy steel, stainless hlau, thiab non-ferrous hlau.

3. Flutes: Lub tshuab kawg yuav muaj ntau lub flutes raws nws qhov ntev. Flutes yog cov helical lossis ncaj grooves rau ntawm qhov kawg zeb. Flutes pab hauv nti khiav tawm thiab muab cov npoo rau tshem tawm cov khoom. Tus naj npawb ntawm flutes tuaj yeem sib txawv nyob ntawm daim ntawv thov, nrog rau kev xaiv ntau yog 2, 4, lossis 6 flutes.

4. Txiav Ntug Geometry: HSS kawg mills tuaj nyob rau hauv ntau yam txiav ntug geometry, xws li square kawg, pob qhov ntswg, kaum vojvoog, los yog chamfer. Txhua geometry yog haum rau kev ua haujlwm milling tshwj xeeb thiab xav tau qhov chaw tiav.

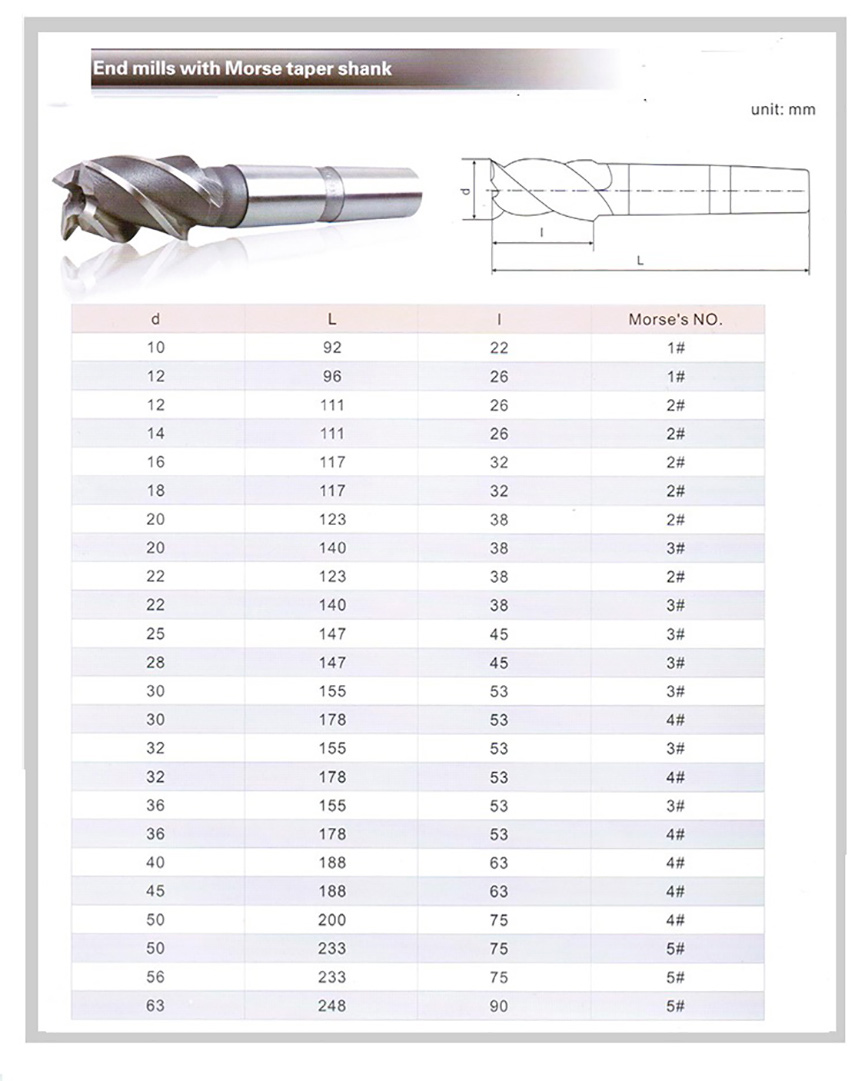

5. Zuag qhia tag nrho Length thiab Flute Length: Lub zuag qhia tag nrho ntev yog hais txog tag nrho qhov ntev ntawm qhov kawg zeb, los ntawm qhov kawg ntawm lub txiav ntug mus rau qhov kawg ntawm lub shank. Lub flute ntev yog hais txog qhov ntev ntawm qhov txiav los yog flutes. Qhov ntev sib txawv muaj los ua kom haum rau qhov sib txawv milling qhov tob thiab qhov xav tau tshem tawm.

6. Kev xaiv txheej: HSS kawg mills kuj tuaj nrog ntau yam txheej txheej xws li TiN, TiCN, lossis TiAlN. Cov txheej txheej no muab kev txhim kho kev hnav tsis kam, ua kom lub neej muaj zog ntxiv, thiab kev ua haujlwm zoo dua hauv kev kub ceev lossis kub-kub txiav.

7. Tus Qauv Loj: Morse Taper shank HSS kawg mills muaj nyob rau hauv cov qauv ntau thiab tsawg uas sib haum rau Morse Taper lub npe (MT1, MT2, MT3, thiab lwm yam). Qhov ntau thiab tsawg no ua kom haum thiab sib haum nrog cov tshuab milling thiab spindles.

Hoobkas

Morse taper shank HSS kawg zeb nthuav dav

Qhov zoo

1. Kev ruaj ntseg thiab raug Mounting: Lub Morse Taper shank muab kev ruaj ntseg thiab meej haum rau hauv cov ntxaiv, txo qhov kev khiav tawm thiab xyuas kom raug txiav. Qhov no pab tswj kom muaj qhov sib npaug ntawm qhov tseeb thiab qhov chaw tiav hauv cov khoom siv machined.

2. Versatility: Morse Taper shank HSS kawg mills muaj nyob rau hauv ntau qhov ntau thiab tsawg thiab geometries, ua rau lawv haum rau ntau yam kev ua haujlwm milling thiab cov khoom siv. Qhov kev siv ntau yam no tso cai rau ntau yam kev siv ntau yam tsis tas yuav muaj ntau yam cuab yeej teeb tsa.

3. Durability thiab Thaum tshav kub kub Resistance: HSS kawg mills paub txog lawv toughness thiab tsis kam mus rau tshav kub. Lawv muaj peev xwm tiv taus siab txiav ceev thiab tswj lawv cov kev ua tau zoo txawm tias nyob rau hauv cov cua sov uas tsim los thaum lub sij hawm machining. Qhov kev ua haujlwm ntev no txhais ua lub neej ntev dua, txo qhov zaus ntawm cov cuab yeej hloov pauv thiab lub sijhawm poob hauv cov txheej txheem machining.

4. Nqi-zoo: HSS kawg mills feem ntau raug nqi ntau dua piv rau lwm cov cuab yeej siv tau zoo, xws li carbide. HSS kawg mills muab qhov sib npaug zoo ntawm kev ua tau zoo thiab tus nqi, ua rau lawv xaiv qhov tsim nyog rau kev ua haujlwm qis dua, cov ntaub ntawv nyuaj, lossis cov ntawv thov uas tsis muaj kev txwv nruj.

5. Compatibility: Morse Taper shank HSS kawg mills yog tsim los ua tau raws li tus qauv Morse Taper spindles feem ntau pom nyob rau hauv milling tshuab. Qhov kev sib raug zoo no ua kom yooj yim rau kev teeb tsa, txo qhov xav tau ntawm cov khoom siv ntxiv, thiab tso cai rau kev hloov pauv yooj yim ntawm cov cuab yeej sib txawv.

6. Resharpening Peev Xwm: HSS kawg mills tuaj yeem hloov kho tau yooj yim, txuas lawv lub neej muaj txiaj ntsig thiab txo cov nqi siv sijhawm dhau sijhawm. Nrog kev saib xyuas kom zoo thiab kev ua kom zoo, HSS kawg zeb tuaj yeem xa cov kev ua tau zoo thiab muaj txiaj ntsig ntawm ntau lub voj voog machining.

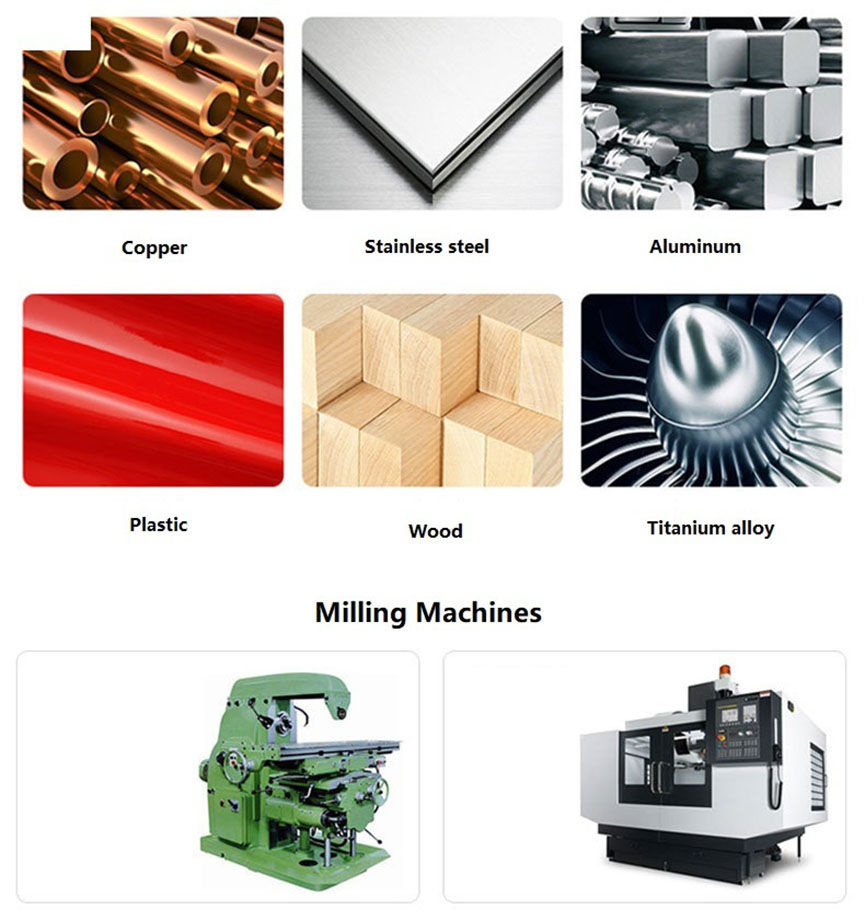

7. Wide Material Compatibility: HSS kawg mills tuaj yeem siv tau ntau yam khoom siv, suav nrog cov hlau, hlau alloy, stainless hlau, cam khwb cia hlau, hlau tsis muaj hlau, thiab yas. Qhov versatility no ua rau lawv haum rau ntau yam kev lag luam thiab kev siv.