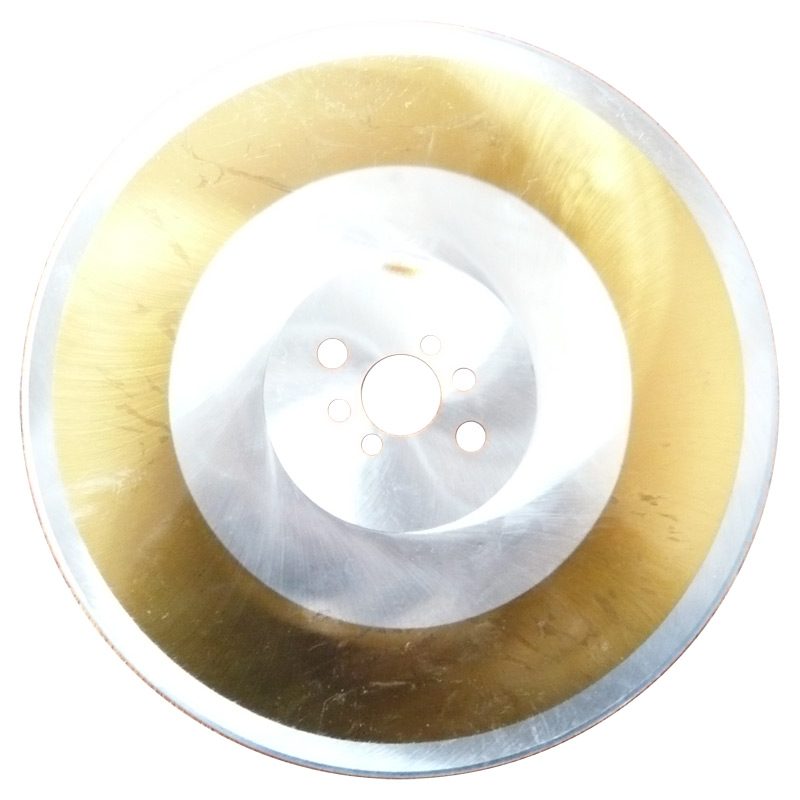

HSS Cobalt M35 Pom Hniav rau Hard Hlau Txiav

Nta

1. Hardness thiab Wear Resistance: HSS cobalt M35 saw hniav yog tsim los ntawm high-speed steel alloy uas yog ntxiv txhim khu kev qha nrog 5% cobalt cov ntsiab lus. Qhov no muaj pes tsawg leeg muab cov hniav tshwj xeeb hardness, tso cai rau lawv tswj lawv cov ntse txiav rau lub sij hawm ntev. Qhov siab ntawm hardness no tseem ua rau lawv hnav tsis kam, kom ntseeg tau tias lawv tuaj yeem tiv taus qhov abrasive ntawm cov hlau tawv thiab tswj lawv cov kev ua haujlwm.

2. Kev Ua Haujlwm Kub Kub Kub: HSS cobalt M35 cov hniav muaj qhov ua kom sov zoo ua tsaug rau cov ntsiab lus cobalt. Qhov no tso cai rau lawv los tswj qhov kub siab uas tsim los thaum txiav cov hlau tsis muaj kev cuam tshuam rau lawv cov hardness lossis durability. Nrog rau kev tiv thaiv tshav kub ntau ntxiv, cov hniav no tuaj yeem tshem tawm cov cua sov kom zoo, txo qhov kev pheej hmoo ntawm overheating, thermal puas, thiab cov hniav hnav ua ntej.

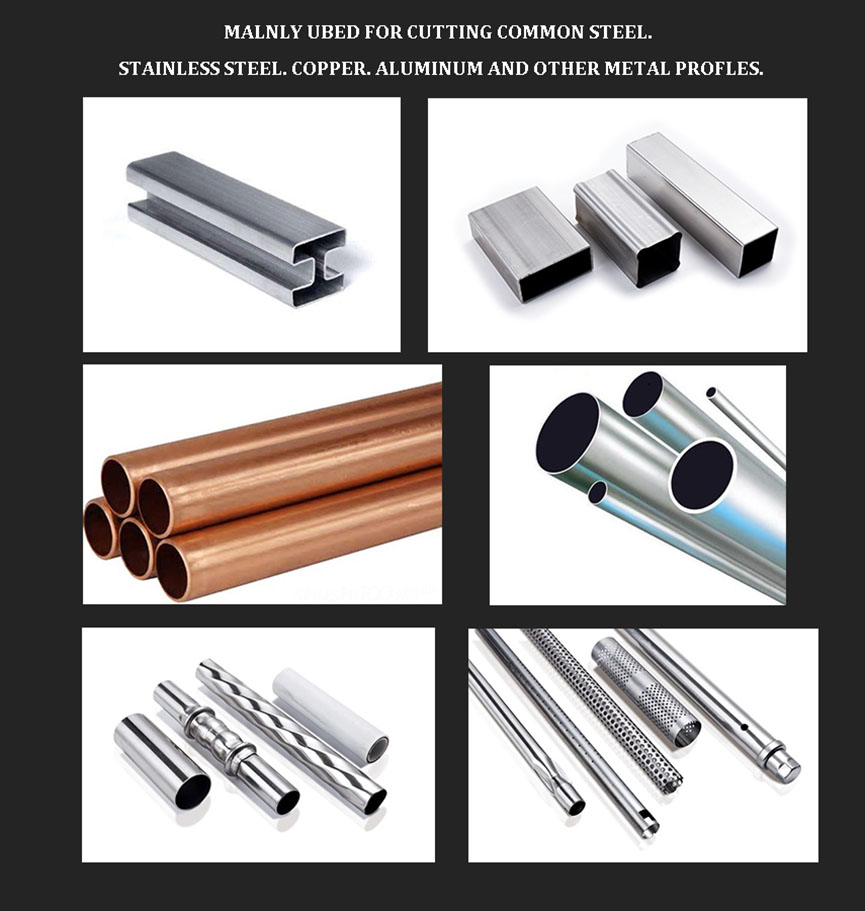

3. Versatility: HSS cobalt M35 hniav yog ntau yam thiab haum rau kev txiav ntau hom tawv hlau. Cov no tuaj yeem suav nrog cov hlau tsis muaj steel, hlau alloy, cov cuab yeej hlau, nickel alloys, thiab lwm yam hlau hardened. Lawv lub peev xwm los daws ntau yam ntaub ntawv ua rau lawv zoo tagnrho rau ntau yam kev siv, xws li hlau fabrication, machining, thiab manufacturing.

4. Kev sib xyaw ua ke ntawm siab hardness, hnav tsis kam, thiab kub ua haujlwm pab txhawb kev txhim kho kev ua haujlwm. HSS cobalt M35 pom cov hniav muab ntxuav, smoother txiav nrog tsawg burrs, txo qhov yuav tsum tau rau lwm yam kev ua tiav tiav. Lawv kuj muab kev txiav ceev thiab kev ua tau zoo, ua kom cov txheej txheem txiav tau sai thiab ua tau zoo dua.

5. Lub neej ntev dua: Qhov tshwj xeeb hardness thiab hnav tsis kam ntawm HSS cobalt M35 cov hniav ua rau lub neej ntev dua piv rau HSS cov hniav. Qhov kev ncua sij hawm ntev no pab txo qis qis qis, txo cov nqi hloov khoom siv, thiab ua kom cov khoom tsim tau tag nrho. Nws kuj ua rau cov hniav no yog qhov kev xaiv zoo rau kev txiav cov hlau nyuaj hauv lub sijhawm ntev.

6. Kev txiav nrawm dua: HSS cobalt M35 cov hniav tso cai rau kev txiav nrawm dua, ua tsaug rau lawv lub peev xwm los tiv thaiv kev ua haujlwm siab dua. Kev txhim kho cua sov ua haujlwm thiab hardness ntawm cov hniav no pab kom lawv tswj tau lawv qhov kev ua tau zoo thiab txiav kev ua tau zoo txawm tias qhov siab ceev. Qhov kev txiav nrawm nrawm no ua rau muaj txiaj ntsig ntau dua thiab txuag lub sijhawm txiav kev ua haujlwm.

7. Txo kev sib txhuam thiab txiav quab yuam: Nrog lawv cov hniav geometry tshwj xeeb thiab txhim kho hardness, HSS cobalt M35 cov hniav tsim kom muaj kev sib txhuam thiab txiav quab yuam thaum txiav hlau. Qhov no ua rau kev txiav txim siab smoother, tsis tshua muaj cua sov, thiab txo qis ntawm ob lub tshuab txiav thiab txiav. Nws kuj pab txo cov khoom distortion los yog workpiece puas thaum lub sij hawm txiav.

hss cobalt saws